Advantages of using CNC machining for precision electronic components

by:Foxron

2021-09-21

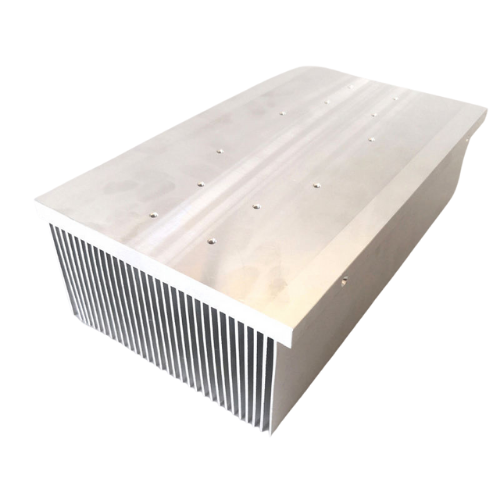

The use of CNC machining of precision electronic components reduces the impact of multiple clamping of the workpiece on the machining accuracy. The machining accuracy of precision electronic components is guaranteed by CNC without manual intervention, which not only reduces the labor intensity of personnel, but also eliminates the impact of human error on product processing. It is especially suitable for mass production processes that do not require high operating skills. Show the advantages of its automatic processing.

The traditional processing methods of precision electronic components must be adjusted frequently during the production process, which takes a lot of time. The work piece shuttles back and forth between processes, which not only has a long cycle, but also increases the waiting time, resulting in lower production capacity, high production costs, and affecting production site management. CNC machining of precision electronic components is superior to traditional machining methods in terms of machining accuracy, quality stability, and requirements for operators.

Nowadays, precision electronic components use group processing technology, through the process of designing group processing technology, group production plane layout for similar parts, controlling and balancing group machine load, group processing time optimization and sorting, etc. A series of production and management processes from group design, manufacturing to management. In the end, an expanded group mass production method was used to improve production efficiency.

The traditional processing methods of precision electronic components must be adjusted frequently during the production process, which takes a lot of time. The work piece shuttles back and forth between processes, which not only has a long cycle, but also increases the waiting time, resulting in lower production capacity, high production costs, and affecting production site management. CNC machining of precision electronic components is superior to traditional machining methods in terms of machining accuracy, quality stability, and requirements for operators.

Nowadays, precision electronic components use group processing technology, through the process of designing group processing technology, group production plane layout for similar parts, controlling and balancing group machine load, group processing time optimization and sorting, etc. A series of production and management processes from group design, manufacturing to management. In the end, an expanded group mass production method was used to improve production efficiency.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121