CNC precision parts processing, how to improve the processing technology of CNC precision parts processing The application of aluminum alloy and CNC precision parts processing technology

by:Foxron

2021-11-30

In the 21st century, machinery and equipment must improve the level of processing, not to mention CNC precision parts processing, in terms of scope, and the effect is even more indispensable. As the market expands faster and faster, the current research and development of machinery and equipment are not However, the processing intensity has not reached the ideal level, so there are certain reasons to improve the processing technology. Now let's understand how to improve the processing technology of CNC precision parts!

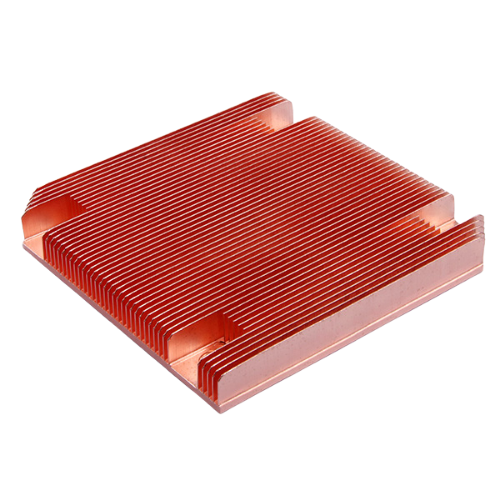

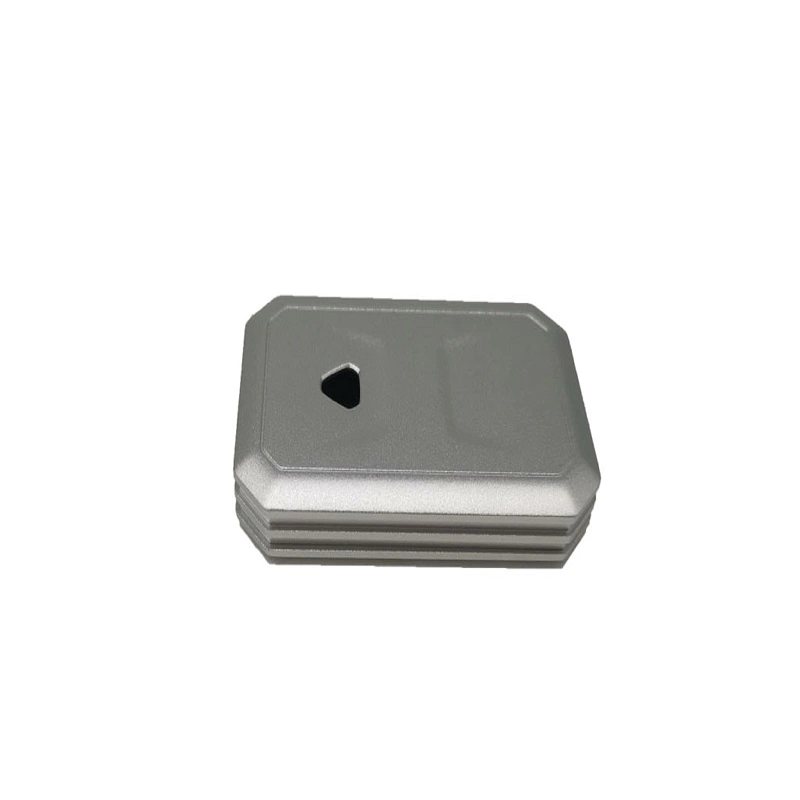

Aluminum alloy is the most widely used non-ferrous metal material in industry. It is widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, chemical industry, household appliances and daily necessities. With the rapid development of science and technology and industrial economy in recent years, the demand for aluminum alloy precision parts is increasing, and the CNC machining process of aluminum alloy has also been studied more and more deeply.

Pure aluminum has low density, low melting point, high plasticity, easy processing, and can be made into various profiles and plates. Good corrosion resistance. Aluminum alloy is obtained by adding other metal elements to metal aluminum to obtain a metal alloy, such as silicon, iron, copper, aluminum, etc. The aluminum alloy obtained by adding other metals has the characteristics of low density, high strength, and corrosion resistance. It is light and portable. The characteristics of aluminum alloy and strength have made aluminum alloys widely used in the processing and manufacturing of various parts, and aluminum alloy parts have been widely used in industry and life.

The wide application of aluminum alloy has promoted the development of aluminum alloy CNC processing technology. At the same time, the development of CNC processing technology has expanded the application field of aluminum alloy. Therefore, the CNC processing technology of aluminum alloy has become a research hotspot. The machining of aluminum alloy parts, also known as CNC machining, automatic lathe machining, CNC lathe machining, etc., is characterized by machining mold parts with general-purpose machine tools such as turning, milling, planing, drilling, and grinding, and then performing necessary fitter repairs and assembly into each Kind of mold; mold parts with high precision requirements, it is difficult to guarantee high machining accuracy only with ordinary machine tools, so precision machine tools are needed for processing; in order to make mold parts, especially punches with complex shapes, concave mold holes and cavity processing More automation, reducing the workload of fitter repairs, need to use CNC machine tools (such as three-axis CNC milling machine, machining center, CNC grinder and other equipment) to process mold parts.

CNC cutting is a processing method that makes cutting more reasonable, and it is also a common process in aluminum alloy precision processing. It uses end mills with multi-directional cutting functions, spiral cutting interpolation, and contour cutting interpolation. , It selects as few tools as possible to process a small number of holes. The unique advantage of CNC machining of aluminum alloy precision parts is that the ball end mill can be used with spiral interpolation to continuously process taper holes; the ball end mill and spiral interpolation drill can be used for boring and chamfering. Machining; End mills can be used with contour cutting interpolation to perform semi-finish machining and precision parts processing; end mills for thread processing can be used with spiral interpolation to process various threaded holes.

Aluminum alloy is the most widely used non-ferrous metal material in industry. It is widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, chemical industry, household appliances and daily necessities. With the rapid development of science and technology and industrial economy in recent years, the demand for aluminum alloy precision parts is increasing, and the CNC machining process of aluminum alloy has also been studied more and more deeply.

Pure aluminum has low density, low melting point, high plasticity, easy processing, and can be made into various profiles and plates. Good corrosion resistance. Aluminum alloy is obtained by adding other metal elements to metal aluminum to obtain a metal alloy, such as silicon, iron, copper, aluminum, etc. The aluminum alloy obtained by adding other metals has the characteristics of low density, high strength, and corrosion resistance. It is light and portable. The characteristics of aluminum alloy and strength have made aluminum alloys widely used in the processing and manufacturing of various parts, and aluminum alloy parts have been widely used in industry and life.

The wide application of aluminum alloy has promoted the development of aluminum alloy CNC processing technology. At the same time, the development of CNC processing technology has expanded the application field of aluminum alloy. Therefore, the CNC processing technology of aluminum alloy has become a research hotspot. The machining of aluminum alloy parts, also known as CNC machining, automatic lathe machining, CNC lathe machining, etc., is characterized by machining mold parts with general-purpose machine tools such as turning, milling, planing, drilling, and grinding, and then performing necessary fitter repairs and assembly into each Kind of mold; mold parts with high precision requirements, it is difficult to guarantee high machining accuracy only with ordinary machine tools, so precision machine tools are needed for processing; in order to make mold parts, especially punches with complex shapes, concave mold holes and cavity processing More automation, reducing the workload of fitter repairs, need to use CNC machine tools (such as three-axis CNC milling machine, machining center, CNC grinder and other equipment) to process mold parts.

CNC cutting is a processing method that makes cutting more reasonable, and it is also a common process in aluminum alloy precision processing. It uses end mills with multi-directional cutting functions, spiral cutting interpolation, and contour cutting interpolation. , It selects as few tools as possible to process a small number of holes. The unique advantage of CNC machining of aluminum alloy precision parts is that the ball end mill can be used with spiral interpolation to continuously process taper holes; the ball end mill and spiral interpolation drill can be used for boring and chamfering. Machining; End mills can be used with contour cutting interpolation to perform semi-finish machining and precision parts processing; end mills for thread processing can be used with spiral interpolation to process various threaded holes.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121