Related Products

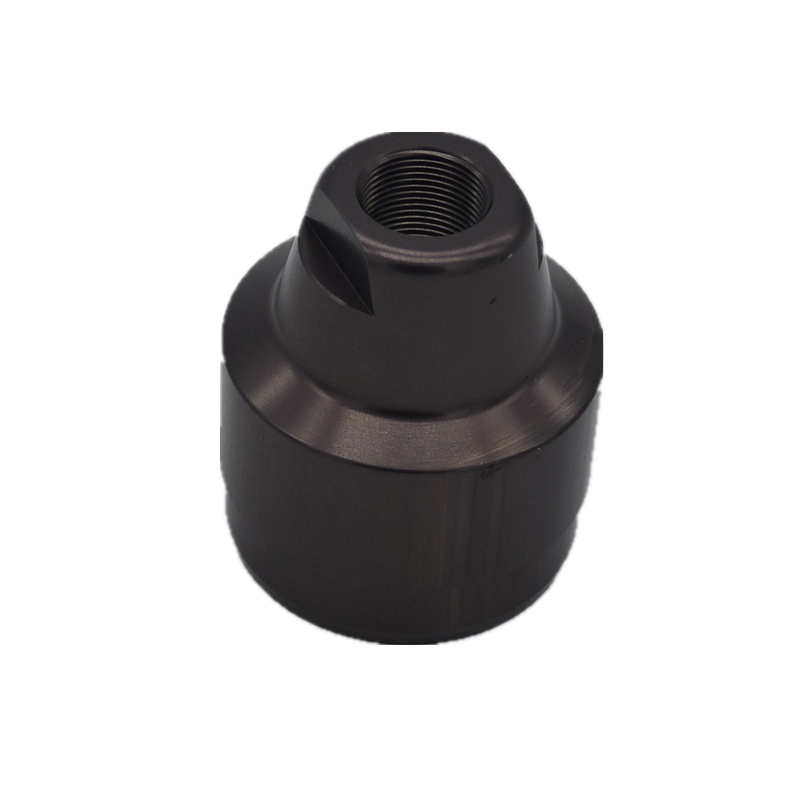

Focusing on precision metal parts manufacturing

Focusing on precision metal parts manufacturing

Copyright © 2019 Dongguan Foxron Precision Metal Parts Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.