Where are the main advantages of precision parts processing?

by:Foxron

2021-09-20

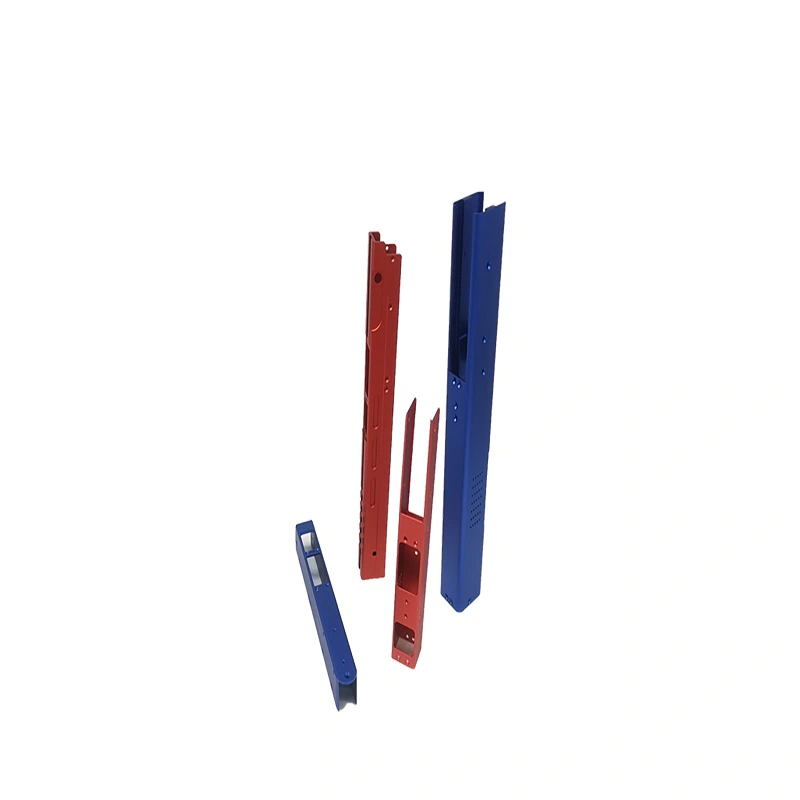

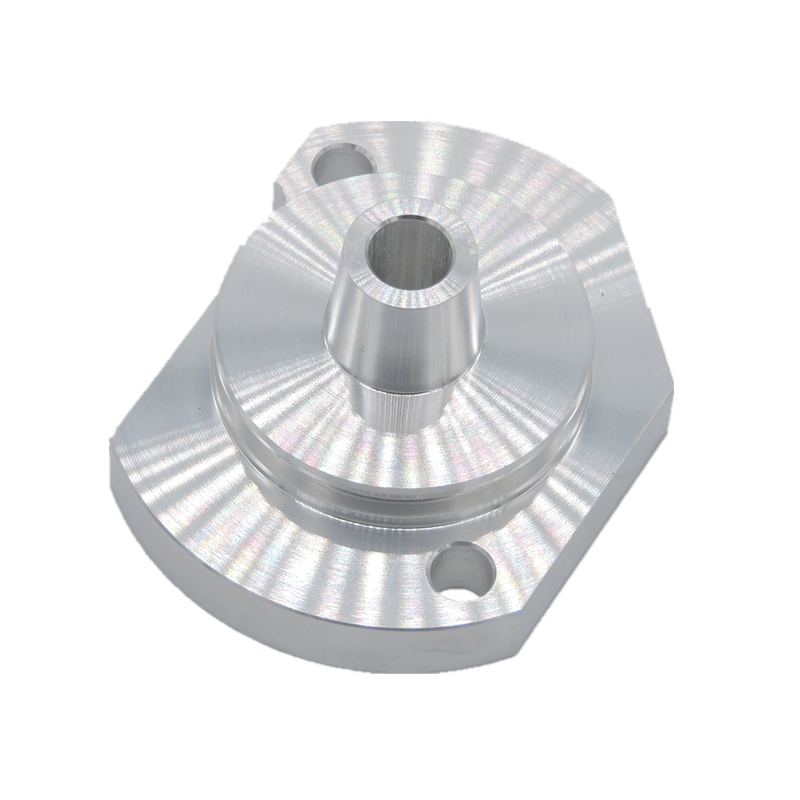

u200bIn precision parts and ordinary parts, more and more people will tend to choose the former. As an integral part of machinery, why are precision parts more popular? What are the benefits of realizing precision parts processing? The following is our chief engineer to introduce to you: When parts are being processed, due to various factors, it is easy to cause certain defects in themselves. For example, the appearance is not up to standard, the scope of use is limited, etc. The existence of these defects is bound to bring certain problems to the use of parts. In order to overcome these problems and give play to the unique value of parts, precision parts processing is the best choice. Choosing precision parts processing can not only effectively improve the material quality, parts accuracy, and exert its functions, but also greatly increase the durability of the parts, and promote the improvement of the quality of the entire machine. Precision processing is also beneficial to improving the dimensional accuracy of the parts. The direct effect is to make the parts interchangeable, thereby increasing the wear resistance and service life of the parts. It is precisely because of the above-mentioned advantages that precision parts processing is so popular. When the equipment is assembled, it can also be used in more suitable fields, so that its value can be maximized. From this point of view, we must pay attention to the processing of precision parts. After processing various parts, we can get more suitable parts. Therefore, in order to allow these products to better serve themselves and play their most extreme value, so many indispensable parts of precision machining. What is machining? Machining is a process of using processing machinery to change the dimensions or performance of a workpiece. According to the temperature state of the workpiece to be processed, it is divided into cold processing and hot processing. Generally processing at room temperature, and does not cause chemical or phase change of the workpiece, called cold working, generally processing at a temperature higher or lower than normal temperature, will cause chemical or phase change of the workpiece, called hot processing. Cold processing can be divided into cutting processing and pressure processing according to the difference of processing methods. Hot processing commonly includes heat treatment, forging, casting and welding. In addition, cold heat treatment is often used during assembly. For example, when assembling a bearing, the inner ring is often placed in liquid nitrogen to cool down to shrink the size, and the outer ring is appropriately heated to enlarge the size, and then assembled together. The outer ring of the train wheel is also heated on the base body, and the firmness of the combination can be ensured when it is cooled.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121