Which tool holders will be used in Dongguan Dongguan Precision Machining?

by:Foxron

2021-11-29

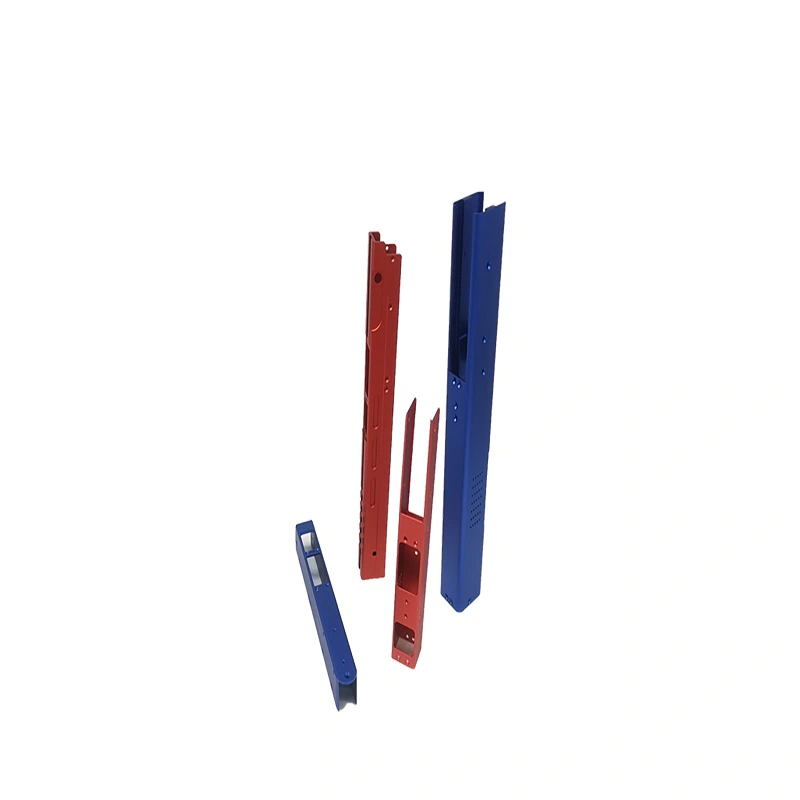

In Dongguan precision machining, all kinds of tools are installed on the CNC tools, and the tool selection and tool postures are carried out at any time and anywhere in strict accordance with the requirements. Therefore, the standardized tool holder must be selected to facilitate the use of drilling, boring, expanding, and cutting processes. The standard tool is quickly and accurately installed on the lathe spindle or CNC tool. The software programmer should master the structure specifications, adjustment methods and adjustment categories of the commonly used tool holders on the CNC lathe, so that the axial and diameter of the tool can be clearly defined when the program is written. To specifications. The most commonly used in China are BT40 and BT50 series of knife handles and pull studs.

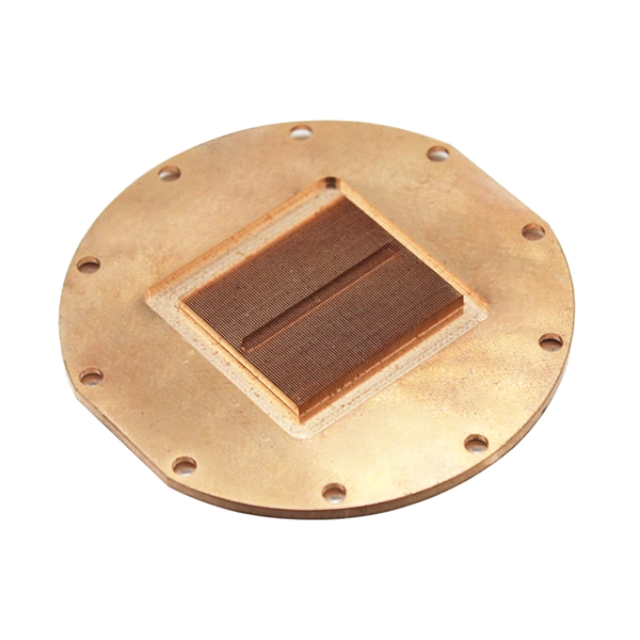

Dongguan Precision Machining Center's commonly used tool holders: flat tool holders, collet chuck holders, powerful chuck holders, face milling cutter holders, face milling cutter holders, side cutter holders, Taper tool holders, drill chuck holders, tap chuck holders, integral tool holders. No tool holder system software is omnipotent. Tool holders designed for high-speed precision parts machining processes generally lack the rigidity and compressive strength required for high-efficiency machining, such as rough machining rough castings. Conversely, tool holders used for rough machining generally lack rotor dynamic balance. This type of rotor dynamic balance can enable tool holders to operate at high speed and stability in the deep machining process.

In addition, the rough design and large volume of the rough tool holder may limit its ability to reach finer or deeper parts. The difficult-to-process raw materials must have a tool holder with improved compressive strength and rigidity. In addition, the shock absorption capability of the tool holder and its refrigerant transportation capability are also key selection criteria. Application of unsuitable tool holders will cause specification deviations and damage to parts, excessive damage to the spindle of the lathe, reduced tool life, and increased risk of tool breakage. In non-critical tasks, a cheap and high-quality knife handle may produce a more satisfactory result. However, in the process flow where repeatable precision must be obtained, especially when the damage of expensive products and workpieces will reduce the gross profit rate of the parts, the high-quality tool holders centered on the project investment can prevent this at a lower cost. Unexpected damage occurred in the class.

The above explained is the tool holders that will be used in Dongguan precision machining. I hope that after reading it, it will be helpful to you. If you want to know more about Dongguan precision machining, please feel free to consult , We will wholeheartedly provide you with quality service!

Dongguan Precision Machining Center's commonly used tool holders: flat tool holders, collet chuck holders, powerful chuck holders, face milling cutter holders, face milling cutter holders, side cutter holders, Taper tool holders, drill chuck holders, tap chuck holders, integral tool holders. No tool holder system software is omnipotent. Tool holders designed for high-speed precision parts machining processes generally lack the rigidity and compressive strength required for high-efficiency machining, such as rough machining rough castings. Conversely, tool holders used for rough machining generally lack rotor dynamic balance. This type of rotor dynamic balance can enable tool holders to operate at high speed and stability in the deep machining process.

In addition, the rough design and large volume of the rough tool holder may limit its ability to reach finer or deeper parts. The difficult-to-process raw materials must have a tool holder with improved compressive strength and rigidity. In addition, the shock absorption capability of the tool holder and its refrigerant transportation capability are also key selection criteria. Application of unsuitable tool holders will cause specification deviations and damage to parts, excessive damage to the spindle of the lathe, reduced tool life, and increased risk of tool breakage. In non-critical tasks, a cheap and high-quality knife handle may produce a more satisfactory result. However, in the process flow where repeatable precision must be obtained, especially when the damage of expensive products and workpieces will reduce the gross profit rate of the parts, the high-quality tool holders centered on the project investment can prevent this at a lower cost. Unexpected damage occurred in the class.

The above explained is the tool holders that will be used in Dongguan precision machining. I hope that after reading it, it will be helpful to you. If you want to know more about Dongguan precision machining, please feel free to consult , We will wholeheartedly provide you with quality service!

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121