by:Foxron

2021-11-24

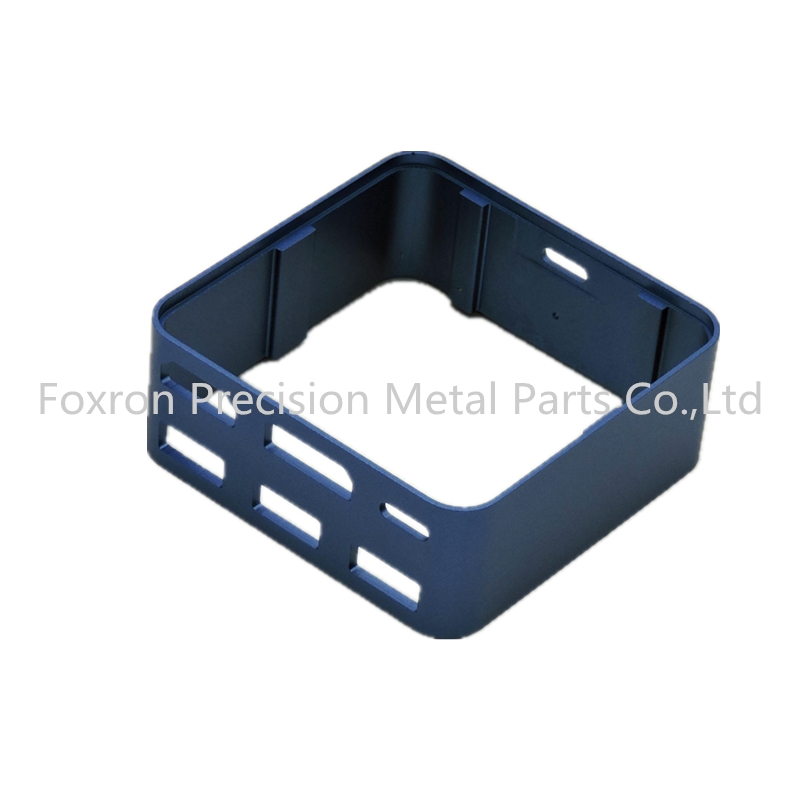

Therefore, if you want to fully understand anodizing, you can't omit all of the following. 1. Is the natural anodizing of the workpiece the same as the anodizing of the workpiece? For these two words, literally, it seems that there is not much difference. However, from a professional point of view, the two are still very different. Realize natural color anodic oxidation through electrolysis. In terms of color, it is known to retain the color before oxidation. Anodizing is the coloring of the oxide film after electrolysis has achieved its purpose. Therefore, the color will change significantly. In addition, the number of steps is more than the number of anodizing services. 2. What is the thickness of the anodic oxide film formed at room temperature? Anodizing is performed at room temperature, and the thickness of the formed oxide film is usually 5 to 15 microns, and the hardness is 200-400HV. The corresponding low-temperature oxidation (called hard oxidation) is different from anodizing. Because of the film thickness, it can reach 250 microns. 3. Are anodized aluminum and electroplated aluminum alloy the same? Although both anodized aluminum alloy and electroplated aluminum alloy have surface treatment on the aluminum alloy material and are similar in form, they are fundamentally different. Due to the anodic oxidation, it is not easy to fall off, and the environmental protection during processing belongs to the third level. Electroplating is easy to fall off, and the environmental protection during processing is first-class. Therefore, there are still many differences.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121