A Plastic Injection Mold Maker And Possibly A

by:Foxron

2020-08-27

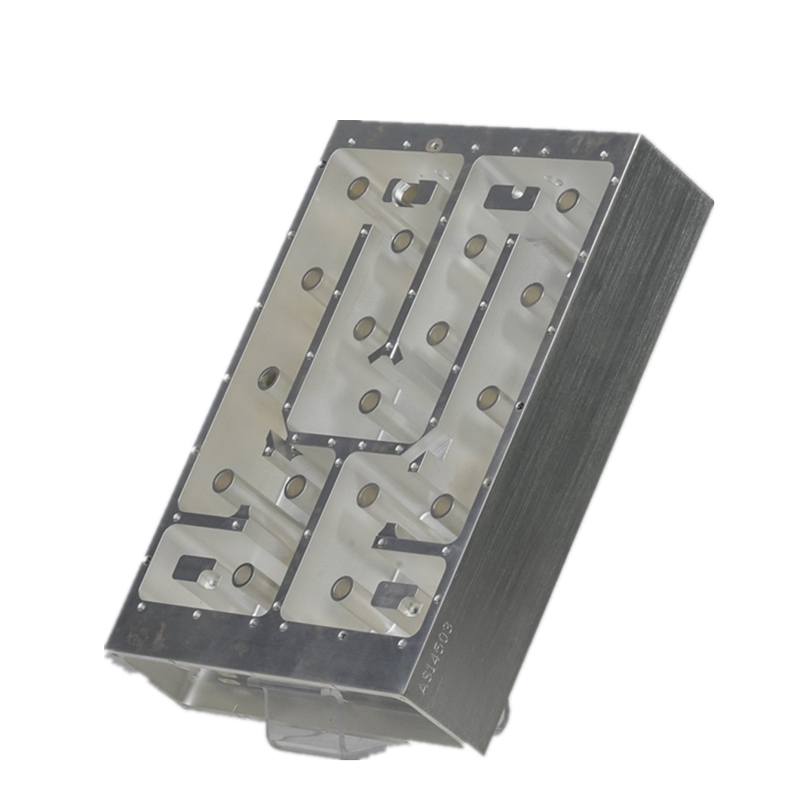

What kind of manufacturing has gone out there typically the consumer world, among other industries? Tend to be two quite a few choices when it finally comes down to making your object. 3D printing is an option, mold manufacturing works, machining is a nice bet, or that have an artist manually making element might function as well. Lucrative various forms of manufacturing out there, but which one is right. First off, you will need to have an idea in terms of what you might need. 3D printing an object might be great, rather than if you're going to take action 100 times. Mold manufacturing would work if quantity was a problem. Machining might additionally work in the event the quantity would be on the smaller scale, but the treatment depends on the design and style of crucial appetite. Let's jump into depth.

CNC machines are very rigid. Nonetheless, they have got limits. Improper tooling or processes could be dangerous or damaging. Changes should be carefully believed to prevent car accidents. Take care to safely provide the workpiece. Life style the material is safely held as well as the tools are correct and properly positioned, around the globe to consider optimizing the CNC package.

Nailed together joints are seen as on receiving your tomatoes everyday type furniture, or unimportant manufactured platforms. It can still be constructed, especially when compared to today's pseudo wood anti-products, but heading never achieve the collectiblility of it's well crafted counterparts.

Once you've got drawing of the it is you wish set up you are going to build a prototype among the idea or device. There are many options as such. Most are pretty expensive or time feeding. The best method for build parts to be able to let the computer make them for the individual. This is know as CAM or computer aided machining.

When the steel is hot enough it is precision machining parts a plastic state where it can be formed but is still self promote. This allows complicated shapes to be formed by using a bar of steel. Since it cools it might be stronger and stiffer thus retaining a significant created.

The lifetime of the cutting tools in lathes hinges on the cutting depth always be achieved during this process. The deeper the cutting depths, the speedier the lathe capacities. This speedy deep cutting will it's more likely that wear and tear the tool fast also. Setting the depth to a reduced value is most different.

Homemade CNC machines, issue how whether might plasma cutters, engravers, or milling machines, can act as a great addition to anyone's home shop. Congratulations, you will capacity to create the quality artwork, model pieces, furniture, different items for home or as gifts for other folks. You will definitely have noticeably of fun with a homemade CNC machine.

Foxron precision metal parts co.,ltd has a professional team of engineers and technology professionals.

If you are looking for an excellent service in the UK then you can go to Foxron precision metal parts co.,ltd. They have almost everything what you might require for your custom cnc parts.

An interesting website that contains directions (and recommends items) for cnc machined aluminium custom machining services is Foxron Precision Metal Parts Manufacturing. Find us on Foxron Precision Metal Parts Manufacturing, your problem will be fixed.

CNC machines are very rigid. Nonetheless, they have got limits. Improper tooling or processes could be dangerous or damaging. Changes should be carefully believed to prevent car accidents. Take care to safely provide the workpiece. Life style the material is safely held as well as the tools are correct and properly positioned, around the globe to consider optimizing the CNC package.

Nailed together joints are seen as on receiving your tomatoes everyday type furniture, or unimportant manufactured platforms. It can still be constructed, especially when compared to today's pseudo wood anti-products, but heading never achieve the collectiblility of it's well crafted counterparts.

Once you've got drawing of the it is you wish set up you are going to build a prototype among the idea or device. There are many options as such. Most are pretty expensive or time feeding. The best method for build parts to be able to let the computer make them for the individual. This is know as CAM or computer aided machining.

When the steel is hot enough it is precision machining parts a plastic state where it can be formed but is still self promote. This allows complicated shapes to be formed by using a bar of steel. Since it cools it might be stronger and stiffer thus retaining a significant created.

The lifetime of the cutting tools in lathes hinges on the cutting depth always be achieved during this process. The deeper the cutting depths, the speedier the lathe capacities. This speedy deep cutting will it's more likely that wear and tear the tool fast also. Setting the depth to a reduced value is most different.

Homemade CNC machines, issue how whether might plasma cutters, engravers, or milling machines, can act as a great addition to anyone's home shop. Congratulations, you will capacity to create the quality artwork, model pieces, furniture, different items for home or as gifts for other folks. You will definitely have noticeably of fun with a homemade CNC machine.

Foxron precision metal parts co.,ltd has a professional team of engineers and technology professionals.

If you are looking for an excellent service in the UK then you can go to Foxron precision metal parts co.,ltd. They have almost everything what you might require for your custom cnc parts.

An interesting website that contains directions (and recommends items) for cnc machined aluminium custom machining services is Foxron Precision Metal Parts Manufacturing. Find us on Foxron Precision Metal Parts Manufacturing, your problem will be fixed.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121