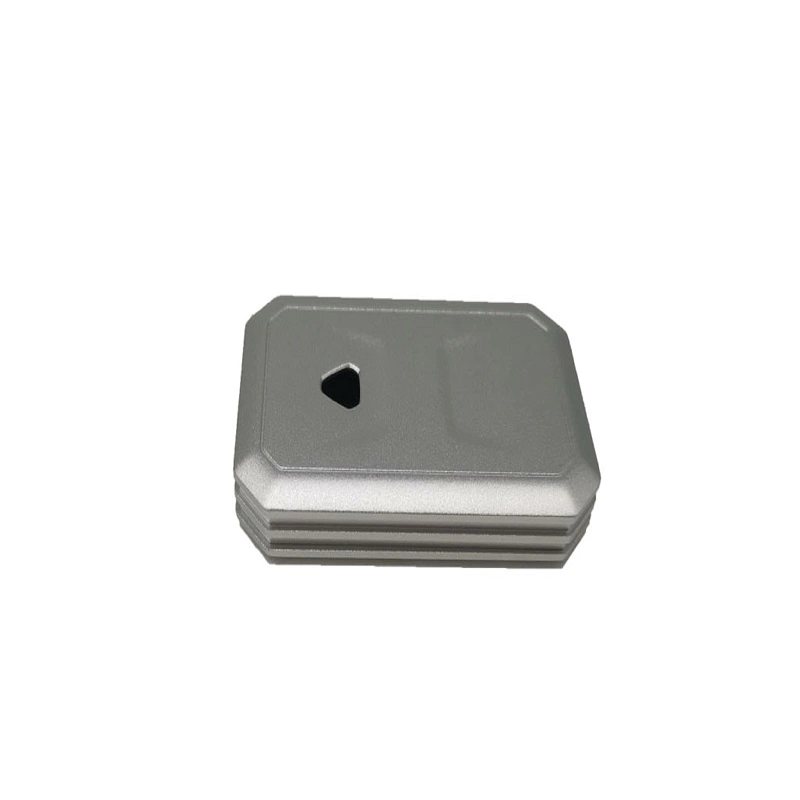

Analysis of the structural characteristics and technical requirements of box parts

by:Foxron

2021-11-14

Generally speaking, the structure of the box body parts is more complicated, the inside is cavity-shaped, and the processing is mainly planes and holes. For the analysis of the technical requirements for box parts, the technical requirements for planes and holes should be analyzed.

1. The accuracy of the plane requires that the design basis of the box body parts is generally a plane. The design basis of each hole system and plane of the box body is G plane, H plane and P plane. Among them, G plane and H plane are also the assembly datum of the box body, so it is There are higher flatness and smaller surface roughness requirements.

2. Technical requirements of the hole system 'A series of holes with hole spacing and coaxiality requirements on the box body are called hole systems. In order to match the box hole with the outer ring of the bearing and the rotation accuracy of the shaft, the dimensional accuracy of the hole is IT7, and the geometric error of the hole is controlled within the dimensional tolerance range. For gear meshing accuracy, the dimensional accuracy between the hole axes, the parallelism between the hole axes, the coaxiality error of the holes on the same axis, and the perpendicularity error of the hole end to the axis should all have higher requirements.

3. Position accuracy between holes and planes Parallelism requirements should be specified between the main holes on the box body and the installation base surface of the box body. The parallelism error of the center line of the main shaft hole of the box part to the assembly base plane (G and H plane) is 0.04mm.

4. Surface roughness The roughness of important holes and the main surface will affect the mating properties or contact stiffness of the connecting surface. The surface roughness of the main holes of the box part is 0.8μm, and the surface roughness of the assembly base surface is 1.6μm.

1. The accuracy of the plane requires that the design basis of the box body parts is generally a plane. The design basis of each hole system and plane of the box body is G plane, H plane and P plane. Among them, G plane and H plane are also the assembly datum of the box body, so it is There are higher flatness and smaller surface roughness requirements.

2. Technical requirements of the hole system 'A series of holes with hole spacing and coaxiality requirements on the box body are called hole systems. In order to match the box hole with the outer ring of the bearing and the rotation accuracy of the shaft, the dimensional accuracy of the hole is IT7, and the geometric error of the hole is controlled within the dimensional tolerance range. For gear meshing accuracy, the dimensional accuracy between the hole axes, the parallelism between the hole axes, the coaxiality error of the holes on the same axis, and the perpendicularity error of the hole end to the axis should all have higher requirements.

3. Position accuracy between holes and planes Parallelism requirements should be specified between the main holes on the box body and the installation base surface of the box body. The parallelism error of the center line of the main shaft hole of the box part to the assembly base plane (G and H plane) is 0.04mm.

4. Surface roughness The roughness of important holes and the main surface will affect the mating properties or contact stiffness of the connecting surface. The surface roughness of the main holes of the box part is 0.8μm, and the surface roughness of the assembly base surface is 1.6μm.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121