CNC CNC precision parts processing methods will also involve die-casting process

by:Foxron

2021-12-01

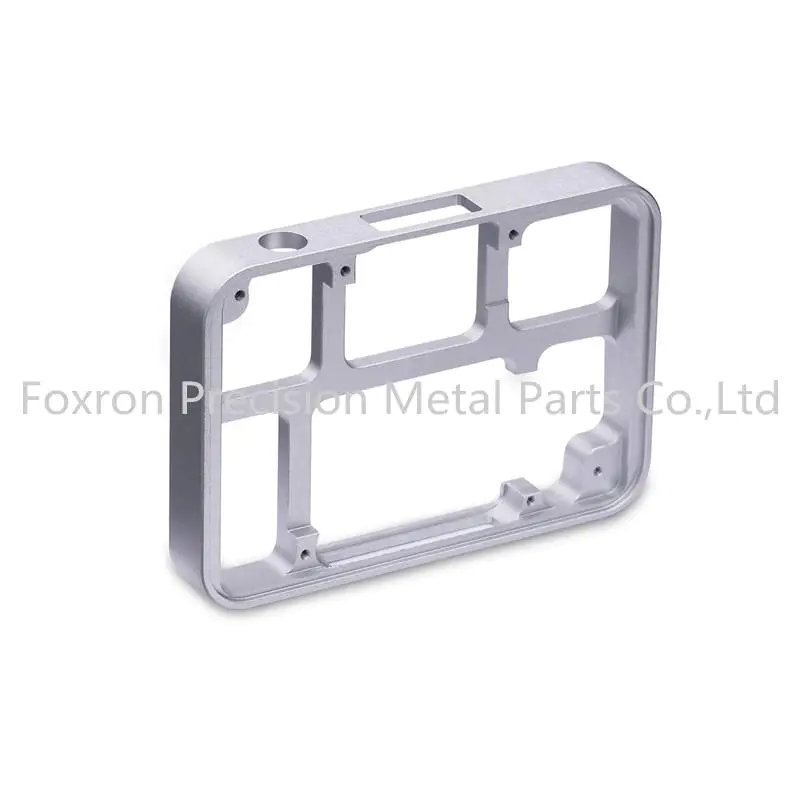

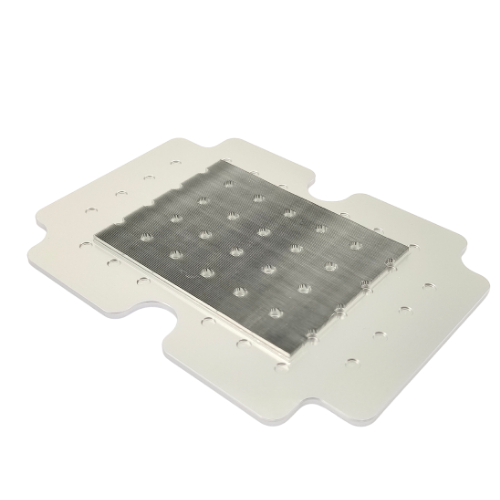

In the industrial field, there are many types of precision parts. Since the technologies involved in each industry are different, the parts used and used are also completely different. Due to the different shapes of parts, in many cases they have to use various processing methods to enhance its quality and related attribute functions. Nowadays, CNC machining methods have been extended to various manufacturing fields, and CNC precision parts machining methods are also a common means to strengthen metal products. As the characteristics of technology continue to improve, its processing quality is gradually upgraded and transformed.

CNC precision parts processing methods will also involve die-casting process.

Die-casting process is the process of unifying pressure, speed and time by using three major elements: machine, mold and alloy. For metal hot processing, the existence of pressure is the main feature of the die-casting process that distinguishes it from other casting methods. Die casting is a kind of special casting method with less cutting and no cutting which has developed rapidly in modern metal processing technology. It is a process in which molten metal is filled into a mold under high pressure and high speed, and crystallized and solidified under high pressure to form a casting. High pressure and high speed are the main characteristics of die casting. The commonly used pressure is tens of megapascals, the filling speed (inner gate speed) is about 16 to 80 m/s, and the time for molten metal to fill the mold cavity is extremely short, about 0.01 to 0.2 seconds. The die-casting process is a process in which the three elements of die-casting machine, die-casting mold and alloy are organically combined and used comprehensively. The process of filling the cavity with metal during die casting is a process of unifying process factors such as pressure, speed, temperature, and time. At the same time, these process factors influence each other, restrict each other, and complement each other. Only by correctly selecting and adjusting these factors and making them coordinated can the expected results be obtained. Therefore, in the process of die-casting, we should not only pay attention to the manufacturability of the casting structure, the advanced nature of the die-casting mold, the performance and structure of the die-casting machine, the adaptability of the die-casting alloy selection and the standardization of the smelting process; more attention should be paid to the pressure, temperature and time. And other process parameters play an important role in the quality of castings. In the die-casting process, attention should be paid to effective control of these parameters.

CNC precision parts processing methods will also involve die-casting process.

Die-casting process is the process of unifying pressure, speed and time by using three major elements: machine, mold and alloy. For metal hot processing, the existence of pressure is the main feature of the die-casting process that distinguishes it from other casting methods. Die casting is a kind of special casting method with less cutting and no cutting which has developed rapidly in modern metal processing technology. It is a process in which molten metal is filled into a mold under high pressure and high speed, and crystallized and solidified under high pressure to form a casting. High pressure and high speed are the main characteristics of die casting. The commonly used pressure is tens of megapascals, the filling speed (inner gate speed) is about 16 to 80 m/s, and the time for molten metal to fill the mold cavity is extremely short, about 0.01 to 0.2 seconds. The die-casting process is a process in which the three elements of die-casting machine, die-casting mold and alloy are organically combined and used comprehensively. The process of filling the cavity with metal during die casting is a process of unifying process factors such as pressure, speed, temperature, and time. At the same time, these process factors influence each other, restrict each other, and complement each other. Only by correctly selecting and adjusting these factors and making them coordinated can the expected results be obtained. Therefore, in the process of die-casting, we should not only pay attention to the manufacturability of the casting structure, the advanced nature of the die-casting mold, the performance and structure of the die-casting machine, the adaptability of the die-casting alloy selection and the standardization of the smelting process; more attention should be paid to the pressure, temperature and time. And other process parameters play an important role in the quality of castings. In the die-casting process, attention should be paid to effective control of these parameters.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121