CNC Machining Process of Precision Stainless Steel Parts

by:Foxron

2021-11-14

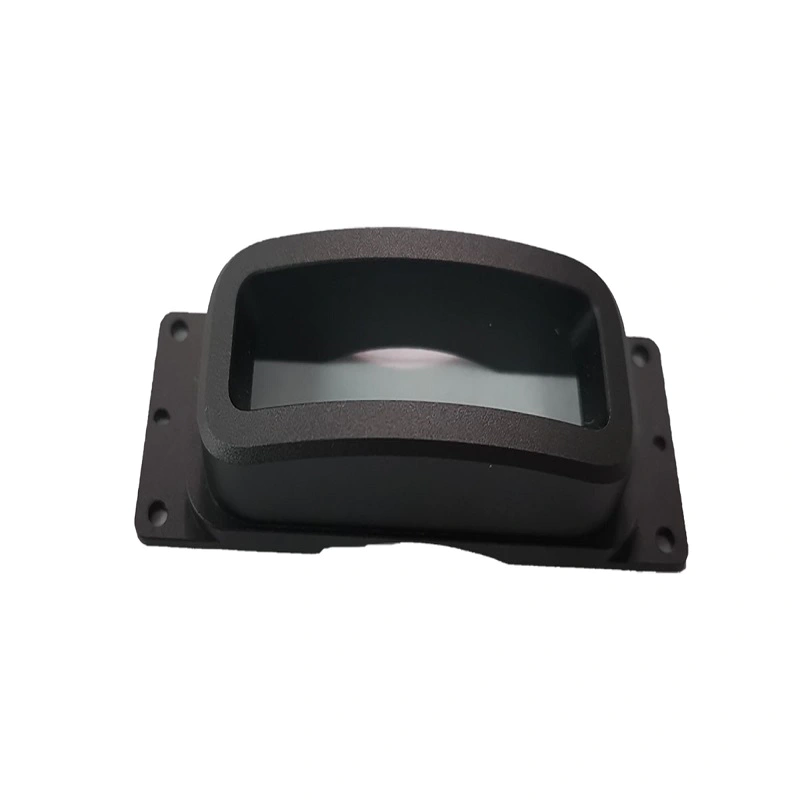

First of all, CNC machining of non-standard precision parts requires extremely strict precision. If you want to achieve ultra-high precision and smooth surface, then the choice of tools is very important. If the tools are worn, the surface of the parts is processed. The quality of smoothness will obviously decrease. When performing ultra-precision machining and cutting, the cutting speed is not restricted by the tool speed. Secondly, when machining non-standard precision parts, the lowest speed is preferred. This is determined by the transmission and cutting characteristics of the machine tool. , Because the minimum speed can ensure that the surface roughness is minimized and the processing quality is guaranteed. Fu Rui Zhizhi is a machining factory with more than ten years of CNC machining experience. It has complete equipment, CNC turning/milling/grinding/drilling/processing. Partners who have parts processing needs are welcome to contact us for quotation. Finally, tell everyone that CNC machining of non-standard precision parts is selected according to the cutting tool, speed, depth and other parameters. Past experience tells us that selecting a tool with a larger rake angle can reduce the cutting force and reduce the deformation. Decrease, the length of the contact time between the tool and the chip will gradually become shorter, reducing the basis of the built-up edge. With the rapid development of aerospace, communications, electronics, medical equipment and other industries, traditional processing technology can no longer meet the processing needs of diversified, batch-oriented, and complex precision stainless steel nozzle parts. The processing industry is moving towards high efficiency, precision and composite The direction of rapid development. Precision parts require high dimensional accuracy and surface roughness. According to the characteristics of this type of parts, most domestic companies adopt CNC machining of parts and design new processing techniques, starting from tool selection and key processing path design, etc., in-depth research and solution This solves the problems of large batches, low efficiency and difficult processing of precision parts. Fu Rui Zhizhi is a machining factory with more than ten years of CNC machining experience. It has complete equipment, CNC turning/milling/grinding/drilling/processing. Partners who have parts processing needs are welcome to contact us for quotation. Stainless steel is a difficult-to-machine material, and there are many processing elements for precision parts, including turning, threading, milling, drilling, boring and so on. Based on comprehensive analysis, the difficulty of precision parts processing is to ensure the dimensional accuracy of the outer circle and the inner hole, the requirements of coaxiality, and the requirements of stable batch processing. For precision parts processing, a precision machine tool that combines multiple processes such as drilling, milling, milling, and tapping at the same time is selected. It has multi-axis indexing function and can perform radial plane milling, drilling and other processes, which effectively solves the problem caused by the turning of the workpiece. The problem of low efficiency and accuracy. By studying the technology of precision CNC composite processing precision stainless steel nozzle parts, it provides technical support for the promotion of new composite processing technology, and also provides a reference for the processing technology of complex and special-shaped parts.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121