Customized effect of mechanical parts processing

by:Foxron

2021-11-17

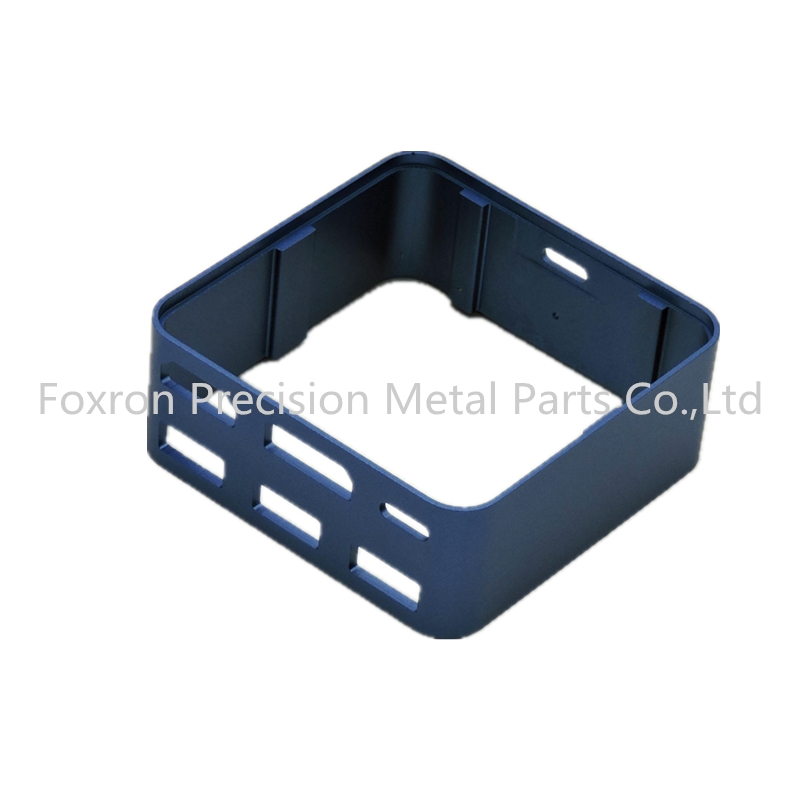

Nowadays, customers who process mechanical parts have relatively high requirements. General precision machining cannot meet their requirements. Custom-made high-precision parts have become their inevitable choice. Under the condition of sufficient assets, such customers will definitely choose to cooperate with the parts processing customization service management center. Although the cost of high-precision parts customization will be much higher, the effect of mechanical parts processing customization is definitely worth the money. .

For new product development companies, which machinery parts processing partners to choose determines the quality of their company's new products. If they develop a new product and choose a general hardware processing factory to show the effect, it will certainly not help them improve the product design. Only with the customized service of mechanical parts processing can we discover the various problems in the design of products, and complete the design in advance.

The forming of mechanical parts is all the function of the tool. The various methods of the tool, such as the wear rate of the ruler side, the knife edge and the back of the tool, are very harmful to the cold work hard layer. In the production process of mechanical parts, the depth and strength of the cold-worked hard layer are also expanded along with the reduction of the ruler side of the tool and the expansion of the wear rate of the knife edge and the back. Drilling with different speeds and cutting speeds has different hazards to cold work and toughness. The cutting speed of mechanical parts processing is expanded, the contact time between the tool and the product workpiece is shorter, the level of plastic deformation is small, and the hardness of cold work is reduced to a certain extent. The cutting speed of the tool increases, the surface cold work hard level increases, and the plastic deformation level increases.

The above-mentioned explanation is that the circuit of the coated power supply is more complicated. I hope it will be helpful to you after reading it. If you want to know more about the related information of the coated power supply, welcome to consult and we will be happy to provide you with Attentive service!

For new product development companies, which machinery parts processing partners to choose determines the quality of their company's new products. If they develop a new product and choose a general hardware processing factory to show the effect, it will certainly not help them improve the product design. Only with the customized service of mechanical parts processing can we discover the various problems in the design of products, and complete the design in advance.

The forming of mechanical parts is all the function of the tool. The various methods of the tool, such as the wear rate of the ruler side, the knife edge and the back of the tool, are very harmful to the cold work hard layer. In the production process of mechanical parts, the depth and strength of the cold-worked hard layer are also expanded along with the reduction of the ruler side of the tool and the expansion of the wear rate of the knife edge and the back. Drilling with different speeds and cutting speeds has different hazards to cold work and toughness. The cutting speed of mechanical parts processing is expanded, the contact time between the tool and the product workpiece is shorter, the level of plastic deformation is small, and the hardness of cold work is reduced to a certain extent. The cutting speed of the tool increases, the surface cold work hard level increases, and the plastic deformation level increases.

The above-mentioned explanation is that the circuit of the coated power supply is more complicated. I hope it will be helpful to you after reading it. If you want to know more about the related information of the coated power supply, welcome to consult and we will be happy to provide you with Attentive service!

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121