In the process of processing precision machinery, what questions should be paid attention to?

by:Foxron

2021-11-27

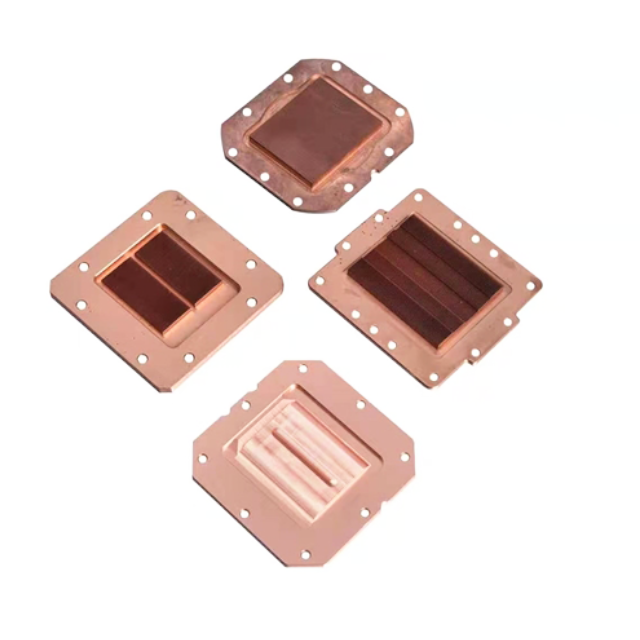

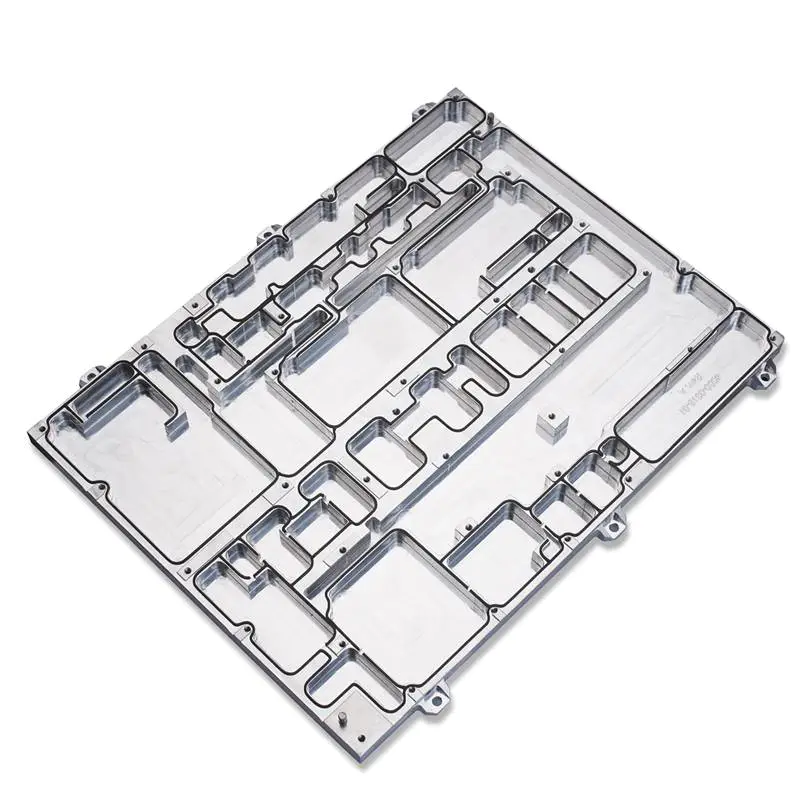

There are many ways of precision machining, such as heat treatment. Parts refer to individual parts that cannot be separated in a machine. They are the basic components of the machine and the basic unit in the machine manufacturing process. The manufacturing process generally does not require an assembly process. Such as sleeves, bushes, nuts, crankshafts, blades, gears, cams, connecting rod bodies, connecting rod heads, etc.

When CNC machine tools are processing precision mechanical parts in batches, special attention should be paid to the precision of the machining. Then what problems should be paid attention to in precision machining?

1. The processing accuracy of batch parts is poor, usually because the feed dynamics between the axes are not adjusted properly according to the error during installation and adjustment, or the transmission chain of each axis of the machine tool has changed due to wear and tear. It can be solved by re-adjusting and modifying the clearance compensation amount. When the dynamic tracking error is too large and the alarm occurs, you can check whether the speed of the servo motor is too high. Whether the position detection element is good. Whether the position feedback cable connector is in good contact. Whether the corresponding analog output latch and gain potentiometer are good. Whether the corresponding servo drive device is normal. 2. The machining accuracy is not good due to overshoot when the machine is in motion. It may be that the acceleration and deceleration time is too short, and the speed change time can be appropriately extended. It may also be that the connection between the servo motor and the lead screw is loose or the rigidity is too poor, and the gain of the position loop can be appropriately reduced. 3. The roundness of the two-axis linkage is out of tolerance. Axial deformation of the circle: This deformation may be caused by improper adjustment of the machine. Poor positioning accuracy of the shaft or improper compensation of the screw gap will cause roundness errors when crossing the quadrant. Oblique ellipse error: At this time, the position deviation value of each axis should be checked first. If the deviation is too large, adjust the position loop gain to eliminate it. Then check whether the interface board of the resolver or induction synchronizer is adjusted well, and then check whether the gap of the mechanical transmission pair is too large and whether the gap compensation is appropriate.

When CNC machine tools are processing precision mechanical parts in batches, special attention should be paid to the precision of the machining. Then what problems should be paid attention to in precision machining?

1. The processing accuracy of batch parts is poor, usually because the feed dynamics between the axes are not adjusted properly according to the error during installation and adjustment, or the transmission chain of each axis of the machine tool has changed due to wear and tear. It can be solved by re-adjusting and modifying the clearance compensation amount. When the dynamic tracking error is too large and the alarm occurs, you can check whether the speed of the servo motor is too high. Whether the position detection element is good. Whether the position feedback cable connector is in good contact. Whether the corresponding analog output latch and gain potentiometer are good. Whether the corresponding servo drive device is normal. 2. The machining accuracy is not good due to overshoot when the machine is in motion. It may be that the acceleration and deceleration time is too short, and the speed change time can be appropriately extended. It may also be that the connection between the servo motor and the lead screw is loose or the rigidity is too poor, and the gain of the position loop can be appropriately reduced. 3. The roundness of the two-axis linkage is out of tolerance. Axial deformation of the circle: This deformation may be caused by improper adjustment of the machine. Poor positioning accuracy of the shaft or improper compensation of the screw gap will cause roundness errors when crossing the quadrant. Oblique ellipse error: At this time, the position deviation value of each axis should be checked first. If the deviation is too large, adjust the position loop gain to eliminate it. Then check whether the interface board of the resolver or induction synchronizer is adjusted well, and then check whether the gap of the mechanical transmission pair is too large and whether the gap compensation is appropriate.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121