Introduce the advantages and disadvantages of CNC machining, the process and the principle of sequence arrangement

by:Foxron

2021-11-14

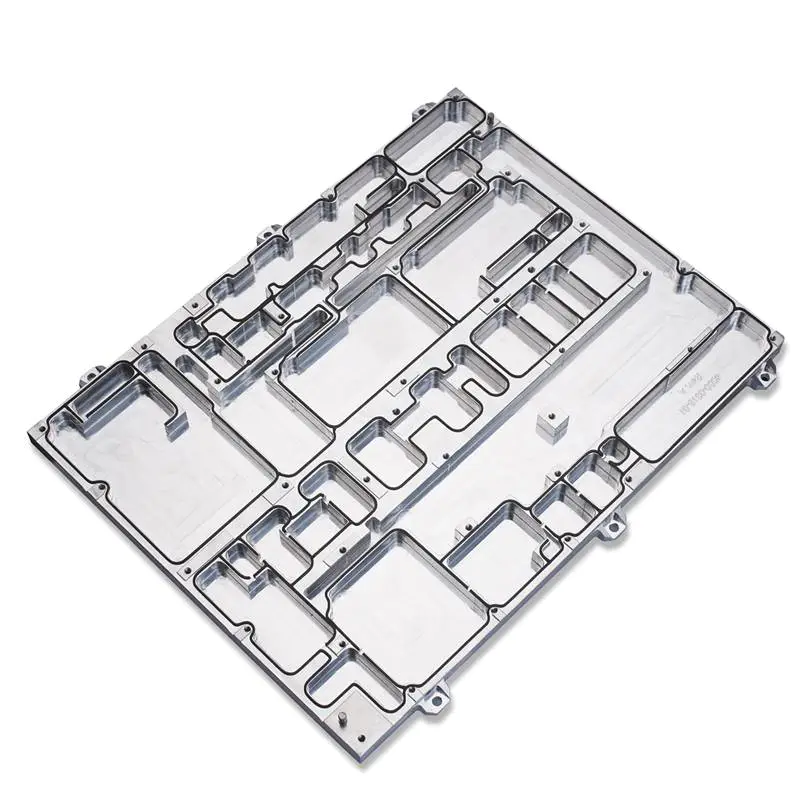

Numerical control processing is a kind of craft, which is widely used in the machinery industry. It refers to the technological process of processing parts on numerically controlled machine tools. In CNC machining, CNC machine tools, CNC systems, etc. are used. CNC machine tools are machine tools controlled by a computer. The instructions of the CNC system are determined by the programmer according to the material of the workpiece, the processing requirements, the characteristics of the machine tool, and the system. A set of instructions prepared in a prescribed instruction format. 1. Advantages and disadvantages of CNC machining: (1) The number of tooling is greatly reduced, and complex tooling is not required for processing parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification. (2) The processing quality is stable, the processing accuracy is high, and the repeat accuracy is high, which is suitable for the processing requirements of the aircraft. (3) The production efficiency is higher in the case of multi-variety and small batch production, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of cutting volume. (4) It can process complex profiles that are difficult to process by conventional methods, and even process some unobservable processing parts. Disadvantages: The cost of machine tool equipment is expensive and requires a high level of maintenance personnel. 2. The process of CNC machining (1) The dimensioning should conform to the characteristics of CNC machining. In CNC programming, the dimensions and positions of all points, lines, and surfaces are based on the origin of the programming. Therefore, the coordinate size is directly given on the part drawing, or the size is quoted on the same basis as far as possible. (2) The conditions of geometric elements should be complete and accurate. In programming, the programmer must fully grasp the geometric element parameters that constitute the contour of the part and the relationship between the geometric elements, because all geometric elements of the part contour must be performed during automatic programming. Definition. When manually programming, the coordinates of each node must be calculated. No matter which point is unclear or uncertain, programming cannot be carried out. However, due to inadequate consideration or neglect by part designers in the design process, there are often incomplete or unclear parameters, such as arc and straight line, arc and arc whether they are tangent or intersected or separated. Therefore, when reviewing and analyzing the drawings, you must be careful and contact the designer in time if you find any problems. (3) The positioning datum is reliable. In CNC machining, the processing procedures are often concentrated, and it is very important to locate on the same datum. Therefore, it is often necessary to set some auxiliary datums, or add some process bosses on the blank. (4) Unified geometry type or size The shape and inner cavity of the parts adopt a unified geometry type or size, which can reduce the number of tool changes, and it is also possible to apply control programs or special programs to shorten the program length. The shape of the parts is as symmetrical as possible, which is convenient for programming with the mirror machining function of the CNC machine tool to save programming time. 3. The principle of sequence arrangement of CNC machining (1) The processing of the previous process cannot affect the positioning and clamping of the next process. (2) Inside first, then outside, that is, the inner cavity is processed, and then the outer shape is processed. (3) The process of machining with the same installation or using the same tool is carried out continuously. (4) In the same installation, procedures that have less impact on the rigidity of the workpiece should be performed. (Picture/text http://www.wxdtc.com/)

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121