Introduction of specific maintenance measures for CNC machine tools

by:Foxron

2021-11-22

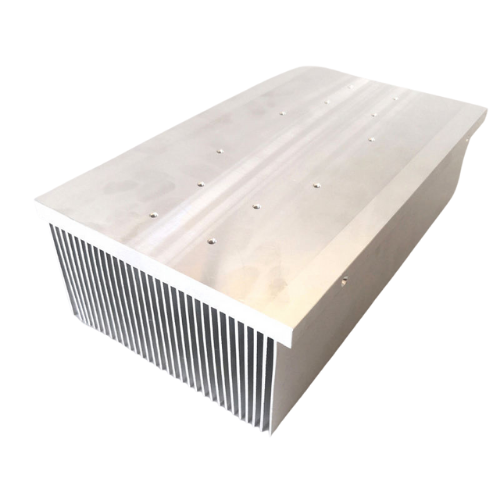

The maintenance of CNC machine tools includes the maintenance of the CNC system, tool magazine and tool change manipulator, ball screw, main drive chain, hydraulic system and pneumatic system. What are the specific maintenance measures for each part? Let's talk about this topic. The specific measures are listed below. 1. Numerical control system (1) Strictly abide by the operating regulations and daily maintenance system of CNC machine tools. (2) Prevent dust from entering the numerical control device: Floating dust and metal powder can easily cause the insulation resistance between components to decrease, resulting in failure or even damage to the components. (3) Regularly clean the heat dissipation and ventilation system of the CNC cabinet. (4) Frequently monitor the grid voltage of the numerical control system: the grid voltage range is 85%—110% of the rated value. (5) Regularly replace the storage battery. (6) Maintenance of the numerical control system when it is not in use for a long time: often power on the numerical control system or make the numerical control machine tool run a warm machine program. 2. Tool magazine and tool change manipulator (1) When manually loading the tool into the tool magazine, install it in place, and check whether the lock on the tool holder is reliable. (2) It is strictly forbidden to load overweight and overlong tools into the tool magazine to prevent the tool from being dropped when the manipulator changes the tool or the tool collides with the workpiece, fixture, etc. (3) When using sequential tool selection, pay attention to whether the order of the tools placed on the magazine is correct. Other tool selection methods should also pay attention to whether the number of the tool to be changed is consistent with the required tool to prevent accidents caused by changing the wrong tool. (4) Pay attention to keep the knife handle and knife sleeve clean. (5) Frequently check whether the zero return position of the tool magazine is correct, check whether the machine spindle return tool change point position is in place, and adjust it in time, otherwise the tool change action cannot be completed. (6) When starting up, the tool magazine and manipulator should be run dry first to check whether each part works normally, especially whether each travel switch and solenoid valve can operate normally. 3. Ball screw (1) Regularly check and adjust the axial clearance of the screw nut pair, reverse transmission accuracy and axial rigidity. (2) Regularly check whether the connection between the screw support and the bed is loose and whether the support bearing is damaged. If there are any of the above problems, tighten the loose parts in time and replace the support bearings. (3) For ball screws with grease, clean the old grease on the screw every six months and replace with new grease. The ball screw lubricated with lubricating oil should be lubricated once a day before the machine tool works. (4) Take care to prevent hard dust or chips from entering the lead screw guard and hitting the guard during work. If the guard is damaged, it should be replaced in time. 4. The main drive chain (1) regularly adjust the tightness of the spindle drive belt. (2) Prevent all kinds of impurities from entering the oil tank, and replace the lubricating oil once a year. (3) To keep the connection between the main shaft and the tool holder clean, the displacement of the hydraulic cylinder and piston must be adjusted in time. (4) Adjust the counterweight in time. 5. Hydraulic system (1) Periodically filter or replace oil. (2) Control the temperature of the oil in the hydraulic system. (3) Prevent leakage of hydraulic system. (4) Regularly check and clean the fuel tank and pipeline. (5) Implement the daily point inspection system. 6. Pneumatic system (1) remove impurities and moisture from compressed air. (2) Check the oil supply of the lubricator in the system. (3) Maintain the tightness of the system. (4) Pay attention to adjusting the working pressure. (5) Clean or replace pneumatic components and filter elements. (Picture/text http://www.wxdtc.com/)

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121