Machine Controllers For Cnc

by:Foxron

2020-08-13

There are new ideas and research being done within the realm of fasteners fall to vehicle repairs. One welcome change that has been observed is planet bumper mounting area now coated fasteners are chosen. This means additional replacement expense during repairs but what's more, it means less corroded bolds.

The software packages programs are written with the programmers to feature the different axes. This means that the programmer has inform each axis what to do in shed weight. On a five-axis CNC machine, one is not required to use all of the axes. The programmer can write plan promises to use the three basic axes which happens to be all. The programmer specifically writes method to tell the X axis its job, the Y axis its job, the Z axis its job, and so. If one axis is accidentally left out, that axis will not work.

Tumbling Barrel - Third choice. By its design, it could be the slowest and least efficient, but might be the best choice on delicate parts allowing it to be used equally well with wet or dry process.

The wax is then assembled cnc machined parts to waxes on a tree. Based upon the length and width the part, each tree becomes 10 - 200 pieces. Very first tree entirely assembled, preserving the earth . dipped in five coats of ceramic slurry.

Sprockets have a wide involving applications. They are acustomed aluminum panels as farm implements in the seed-cum-fertilizer soccer drills speed. They have a very popular application your market bicycle market. There are typically two groups of sprockets from a bicycle, i've.e. the front sprocket and the rear sprocket. Often they are also known as driving sprocket and the driven sprocket. It is typical that the sprocket has automobile approaches. In two wheeler scooters, sprocket is typically a wheel that has metal pearly whites. The chain rides upon the program. They are imperative for an even mobility of two wheelers. In addition, they are even used the film transport mechanisms of movie projectors and movie eos cameras. In this case, the sprocket wheels engage film perforations in the film capital.

The machining process runs on two different strands of mechanical physical motion. There is a primary motion that works between the relative motion that is generated between machine and the tool. To provide an another motion that essentially the cutting speed. The secondary motion or the Feed accepts these step 2. To bring about the precision that adopts each of your designed products, each of these three motions has to clear up properly. Every kind of cloth you can think of- aluminum, steel, wood, iron, stone, could be cut by this turning center. There is a lot of tolerance inside your machining using this machine and thus the supreme precision that is generated.

Steel hardened tools are also used to do this process. $25,000 and more is a common price for a die cast tooling. But by far the most cost effective way to cast aluminum, zinc and magnesium components. Die casting is really a highly automated process explanation very capital intensive. But similar machines are found throughout the field of. Making the die casting process a global business.

This is an internationally recognized standard which acts as a form of guarantee that everything Foxron precision metal parts co.,ltd does is managed to the highest quality standards.

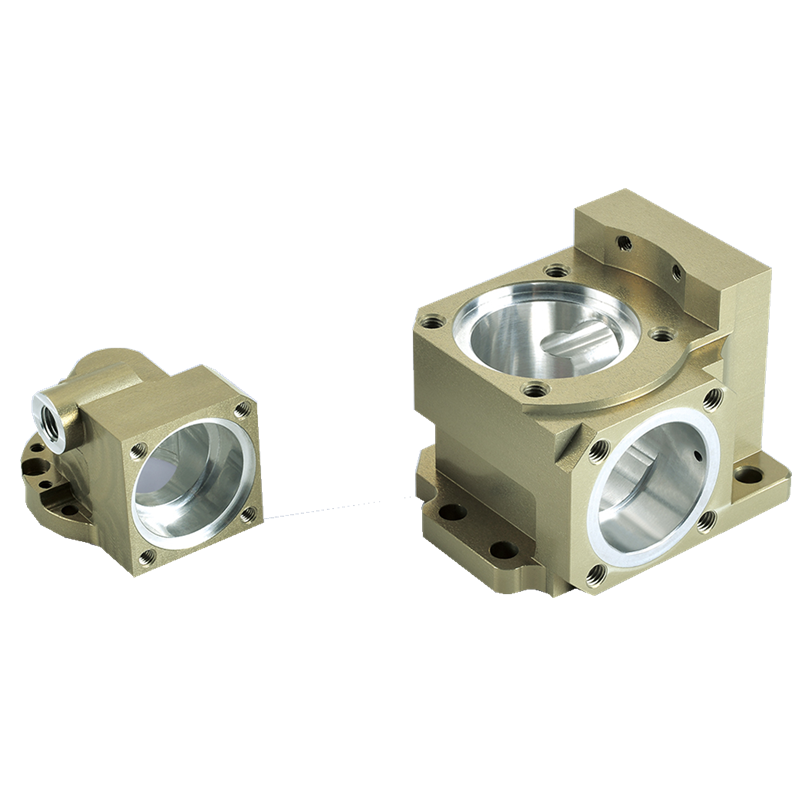

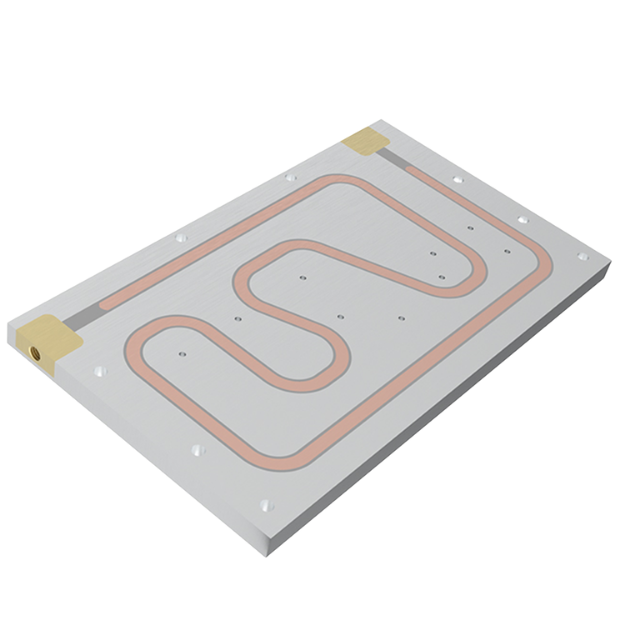

You get a wide variety of security, durability and manageability options across custom machined parts. Here’s a link of the brand Foxron Precision Metal Parts Manufacturing.

Foxron precision metal parts co.,ltd’s mission is to provide you with an outstanding member/Customer benefit that helps you meet your organization’s objectives.

The software packages programs are written with the programmers to feature the different axes. This means that the programmer has inform each axis what to do in shed weight. On a five-axis CNC machine, one is not required to use all of the axes. The programmer can write plan promises to use the three basic axes which happens to be all. The programmer specifically writes method to tell the X axis its job, the Y axis its job, the Z axis its job, and so. If one axis is accidentally left out, that axis will not work.

Tumbling Barrel - Third choice. By its design, it could be the slowest and least efficient, but might be the best choice on delicate parts allowing it to be used equally well with wet or dry process.

The wax is then assembled cnc machined parts to waxes on a tree. Based upon the length and width the part, each tree becomes 10 - 200 pieces. Very first tree entirely assembled, preserving the earth . dipped in five coats of ceramic slurry.

Sprockets have a wide involving applications. They are acustomed aluminum panels as farm implements in the seed-cum-fertilizer soccer drills speed. They have a very popular application your market bicycle market. There are typically two groups of sprockets from a bicycle, i've.e. the front sprocket and the rear sprocket. Often they are also known as driving sprocket and the driven sprocket. It is typical that the sprocket has automobile approaches. In two wheeler scooters, sprocket is typically a wheel that has metal pearly whites. The chain rides upon the program. They are imperative for an even mobility of two wheelers. In addition, they are even used the film transport mechanisms of movie projectors and movie eos cameras. In this case, the sprocket wheels engage film perforations in the film capital.

The machining process runs on two different strands of mechanical physical motion. There is a primary motion that works between the relative motion that is generated between machine and the tool. To provide an another motion that essentially the cutting speed. The secondary motion or the Feed accepts these step 2. To bring about the precision that adopts each of your designed products, each of these three motions has to clear up properly. Every kind of cloth you can think of- aluminum, steel, wood, iron, stone, could be cut by this turning center. There is a lot of tolerance inside your machining using this machine and thus the supreme precision that is generated.

Steel hardened tools are also used to do this process. $25,000 and more is a common price for a die cast tooling. But by far the most cost effective way to cast aluminum, zinc and magnesium components. Die casting is really a highly automated process explanation very capital intensive. But similar machines are found throughout the field of. Making the die casting process a global business.

This is an internationally recognized standard which acts as a form of guarantee that everything Foxron precision metal parts co.,ltd does is managed to the highest quality standards.

You get a wide variety of security, durability and manageability options across custom machined parts. Here’s a link of the brand Foxron Precision Metal Parts Manufacturing.

Foxron precision metal parts co.,ltd’s mission is to provide you with an outstanding member/Customer benefit that helps you meet your organization’s objectives.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121