Machining?

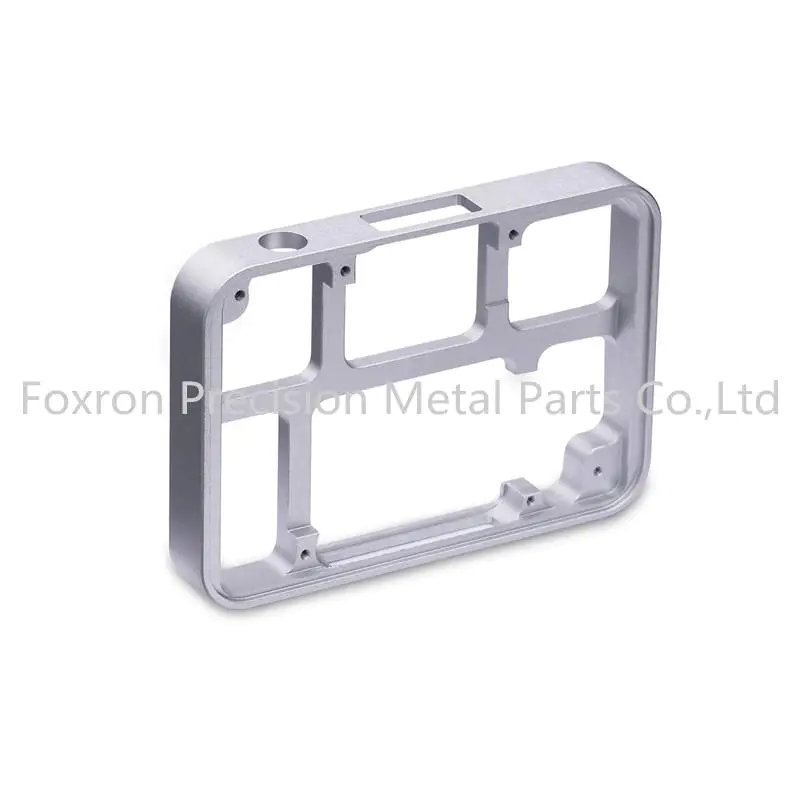

by:Foxron

2021-09-19

Core walking machine-full name is walking core CNC lathe, it can also be called headstock movable CNC automatic lathe, economical turning-milling compound machine tool or slitting lathe. It is a precision processing equipment that can complete lathe, milling, drilling, boring, tapping, engraving and other compound processing at the same time. It is mainly used for batch processing of precision hardware and shaft special-shaped non-standard parts. This machine tool first originated in Germany and Switzerland, and was mainly used for precision processing of military equipment in the early stage. With the continuous development and expansion of the industrialization process, due to the urgent market demand, it is gradually used in the processing of civilian products. The core machine has a qualitative leap in machining efficiency and machining accuracy compared to CNC lathes. Thanks to the dual-axis arrangement of tools, the machining cycle time is greatly reduced. By shortening the tool exchange time between the gang tool and the opposed tool station, multiple tools Table overlap function, thread chip effective axis movement overlap function, direct spindle indexing function during secondary processing, realize the shortening of idling time. The chip cutting tool is always processed on the clamping part of the spindle and the workpiece, which ensures the constant processing accuracy. At present, the maximum machining diameter of the core machine on the market is 32mm, which has a great advantage in the precision shaft machining market. This series of machine tools can be equipped with automatic feeding devices to realize fully automated production of a single machine tool, reducing labor costs and product defect rates. It is very suitable for mass production of precision shaft parts. Features and advantages: (1) Shorten the product manufacturing process chain and improve production efficiency. Turning and milling combined processing can complete all or most of the processing procedures at one time, thus greatly shortening the product manufacturing process chain. In this way, on the one hand, the production assistance time caused by the change of the installation card is reduced, and the manufacturing cycle and waiting time of the tooling fixture are also reduced, which can significantly improve the production efficiency. (2) Reduce the number of clamping and improve processing accuracy. The reduction in the number of card loading avoids the accumulation of errors due to the conversion of positioning benchmarks. At the same time, most of the turning-milling composite processing equipment has the function of online detection, which can realize the in-situ detection and precision control of key data in the manufacturing process, thereby improving the processing accuracy of the product. (3) Reduce floor space and production cost. Although the price of a single unit of turning-milling composite processing equipment is relatively high, due to the shortening of the manufacturing process chain and the reduction of equipment required for products, as well as the reduction in the number of fixtures, workshop area and equipment maintenance costs, it can effectively reduce the overall fixed assets The cost of investment, production operation and management.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121