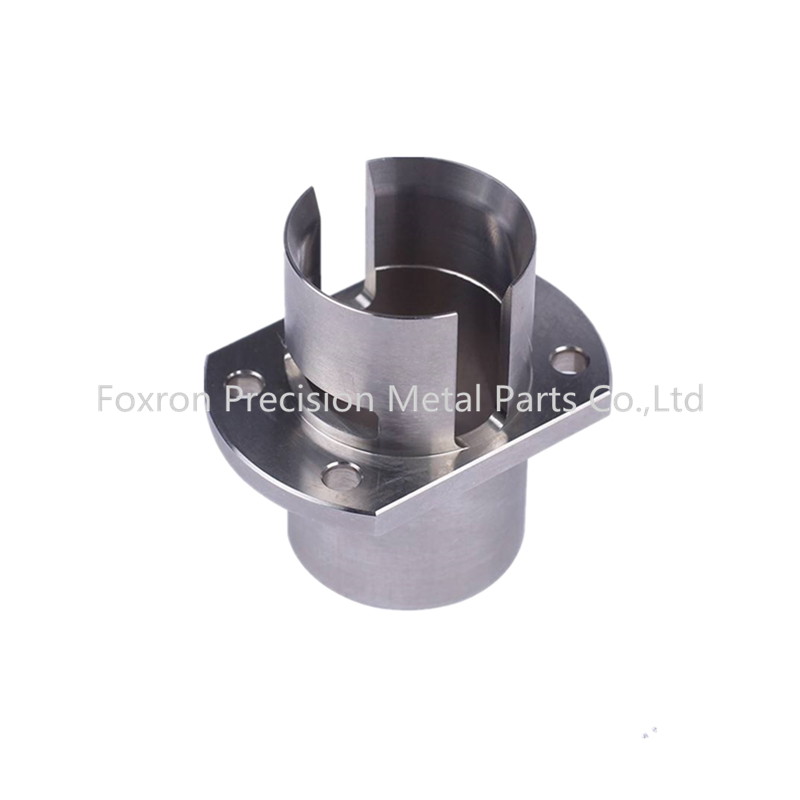

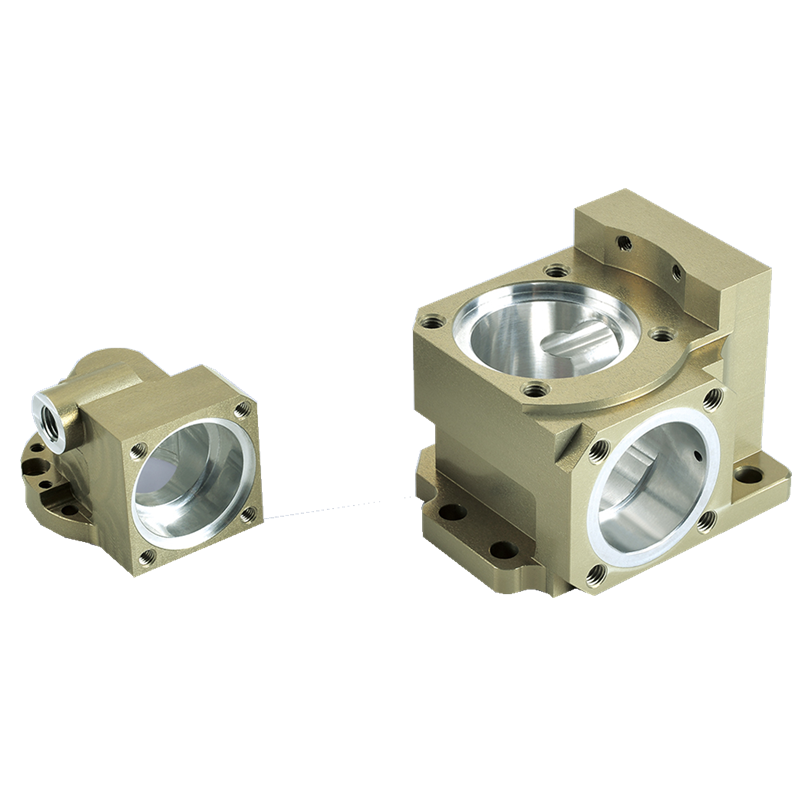

Quality End Products With Cnc Lathes

by:Foxron

2020-10-02

High quality cutting systems have solid, heavy-duty, fully welded unitized construction. Huge a solid, stable, platform that could be the foundation for accurate, repeatable plasma shearing. The time invested in creating fully welding the working platform results in higher initial cost.

Based on his or her number of strands, sprockets can be classified into various forms of. Firstly, the split type sprocket can be a good alternative for solid type permits quick installation without any kind of way hampering the shaft and stance. Secondly, taper bushed sprocket (TB) a great interchangeable bushed sprocket providing a positive grip across the driven shaft. Thirdly, there is a sort of quick detachable (QD) sprocket. In this particular type a tapered bushing is typically bolted in the bore is actually machined your market sprocket. A decent grip is supplied as the bushing is inserted into the sprocket, which compresses on the shaft.

The third tip would be consider using a third-party auto shop attributes needed car a peek over. That you will find to pay out of your individual pocket, but if you start making serious about purchasing a small vehicle, spending a $ 100 or now could protect your potentially money in future repair the costs.

That was the easy part. Now you need to get tire off wheel. There is a trick to accomplishing this without using tire golf irons. It just takes some practice to obtain the practice of it. Become more serious . you comprehend the practice of it you'll be able to get a tire without risking damage towards tire or wheel anyone will be risking if you use tire irons. An issue inside on the tire, roll the the surface of the tire inward, therefore bottom tire bead extend itself inside the rim. Grab the extended bead and slowly work the tire off the rim until the entire bead has been removed this rim.

This process is gaining ground associated with medical device field. It's major disadvantage is that tooling is very expensive, $25,000 and right up. But it does give you great precision machining parts as well as a relatively low piece price for high volume portions.

Ejector and core pin holes. While almost all knock out holes are WEDMd these days, factors still applications when much more sense to jig grind them.

The typical toolmaker has moved to a technical school and served an apprenticeship for 4 years. On top of this, techniques usually a lot of of special classes and training programs that they participate in.

Foxron precision metal parts co.,ltd undertakes bulk operations and specializes in undertaking corporate offers to cater the needs of different companies.

Above all, we expect to be a credit to the communities we serve, a valuable resource to our customers, and a place where our dedicated custom machined parts can grow and prosper.

Obviously, financial return is important in manufacturing cnc machined aluminium, but I think that's not enough. I think many customers want to support something they really believe in.

Based on his or her number of strands, sprockets can be classified into various forms of. Firstly, the split type sprocket can be a good alternative for solid type permits quick installation without any kind of way hampering the shaft and stance. Secondly, taper bushed sprocket (TB) a great interchangeable bushed sprocket providing a positive grip across the driven shaft. Thirdly, there is a sort of quick detachable (QD) sprocket. In this particular type a tapered bushing is typically bolted in the bore is actually machined your market sprocket. A decent grip is supplied as the bushing is inserted into the sprocket, which compresses on the shaft.

The third tip would be consider using a third-party auto shop attributes needed car a peek over. That you will find to pay out of your individual pocket, but if you start making serious about purchasing a small vehicle, spending a $ 100 or now could protect your potentially money in future repair the costs.

That was the easy part. Now you need to get tire off wheel. There is a trick to accomplishing this without using tire golf irons. It just takes some practice to obtain the practice of it. Become more serious . you comprehend the practice of it you'll be able to get a tire without risking damage towards tire or wheel anyone will be risking if you use tire irons. An issue inside on the tire, roll the the surface of the tire inward, therefore bottom tire bead extend itself inside the rim. Grab the extended bead and slowly work the tire off the rim until the entire bead has been removed this rim.

This process is gaining ground associated with medical device field. It's major disadvantage is that tooling is very expensive, $25,000 and right up. But it does give you great precision machining parts as well as a relatively low piece price for high volume portions.

Ejector and core pin holes. While almost all knock out holes are WEDMd these days, factors still applications when much more sense to jig grind them.

The typical toolmaker has moved to a technical school and served an apprenticeship for 4 years. On top of this, techniques usually a lot of of special classes and training programs that they participate in.

Foxron precision metal parts co.,ltd undertakes bulk operations and specializes in undertaking corporate offers to cater the needs of different companies.

Above all, we expect to be a credit to the communities we serve, a valuable resource to our customers, and a place where our dedicated custom machined parts can grow and prosper.

Obviously, financial return is important in manufacturing cnc machined aluminium, but I think that's not enough. I think many customers want to support something they really believe in.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121