Several methods of KOVAR parts processing, personal experience tells you the pros and cons of various methods

by:Foxron

2021-10-02

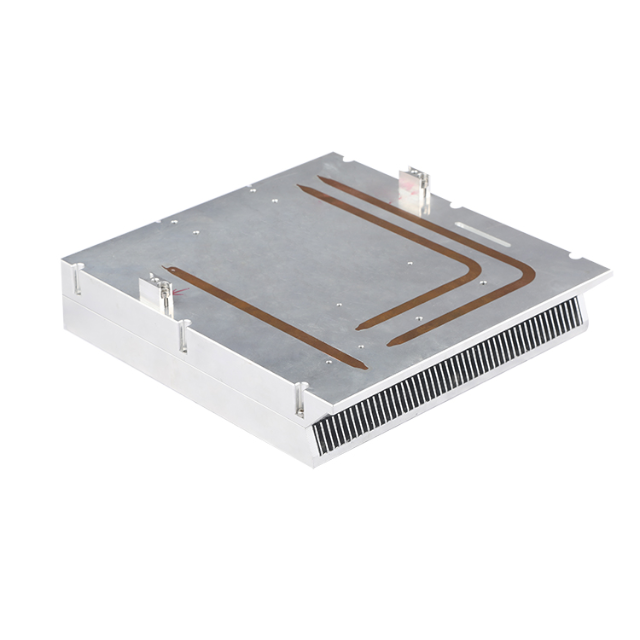

u200bKOVAR parts are also called Kovar alloy parts. KOVAR parts processing products are mainly used for glass sintering, so Kovar alloy parts are mainly made of cavity structure, that is, parts products generally have internal space for placing electronic structural parts. Glass sintered sealing. The main machining methods of Kovar alloy machining parts are CNC machining and CNC core-moving machining. Kovar CNC machining is mainly for the production of square cavity structure parts, and Kovar CNC core-moving machining is mainly for Production of cylindrical cavity structure. CNC machining and CNC core-moving machining are collectively referred to as machining. Kovar alloy materials have relatively high plasticity, so Kovar alloys are prone to sticking to the tool, especially for Kovar drilling and tapping. It is not too high. In addition, a large amount of material will be dug out to form space when machining the cavity, so the material utilization rate of Kovar machining parts is not high, generally less than 50%. These are the drawbacks of Kovar machining. However, if the customer orders for Kovar alloy products are small, machining is the only more convenient processing method. I have encountered a few customers who have a great demand for KOVAR parts, because the machining speed is really unable to keep up with the customer's needs, and the story was made by forcing Stande Hardware to choose other processing methods. Tell it and share it with you. , In order to achieve common progress. In 2017, Stand Hardware received a Korean customer who needed 50,000 Kovar alloy products per month. The product is a hollow product with a length, width and height of 30*15*10mm and a wall thickness of 1mm. If it is processed by CNC, one It is that the output cannot meet the needs of customers, and the second is that the cost cannot meet the needs of customers. Although I tried the powder metallurgy process, but because Kovar alloy contains too much nickel, this process cannot be used. Later, we focused on the research and development personnel, and came up with the Kovar alloy strip material to use the stretching process to make this cavity. Through actual testing, it fully meets the requirements of customers, and the mass production speed and cost unit price can also meet the requirements of customers. It was resolved satisfactorily. There is also a cavity made of Kovar alloy. The shape is relatively ordinary. Like a match box, it needs to be hollowed out on three sides. This cannot be done by stretching. It must be extruded by a press of more than 300 tons. When the method is completed, Stand Hardware is still very experienced in Kovar alloy extrusion, but this kind of cavity to open continuous cold extrusion die is still relatively expensive, usually above 70-80,000 RMB, so Kovar alloy processing parts If you don’t have an order of more than 200,000 yuan, you don’t need to consider it.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121