What are the advantages of aluminum alloy?

by:Foxron

2021-10-01

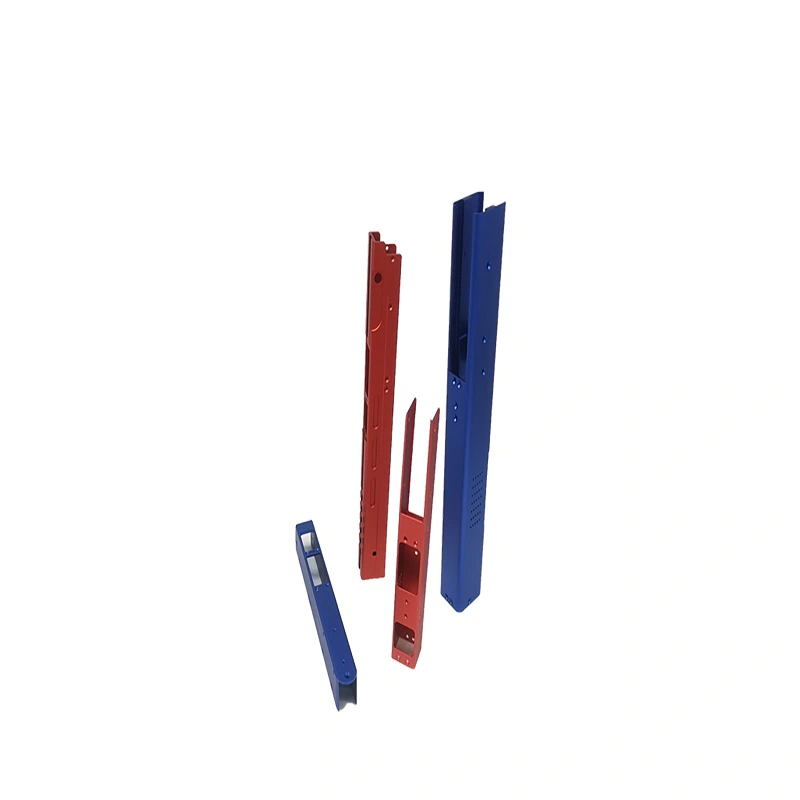

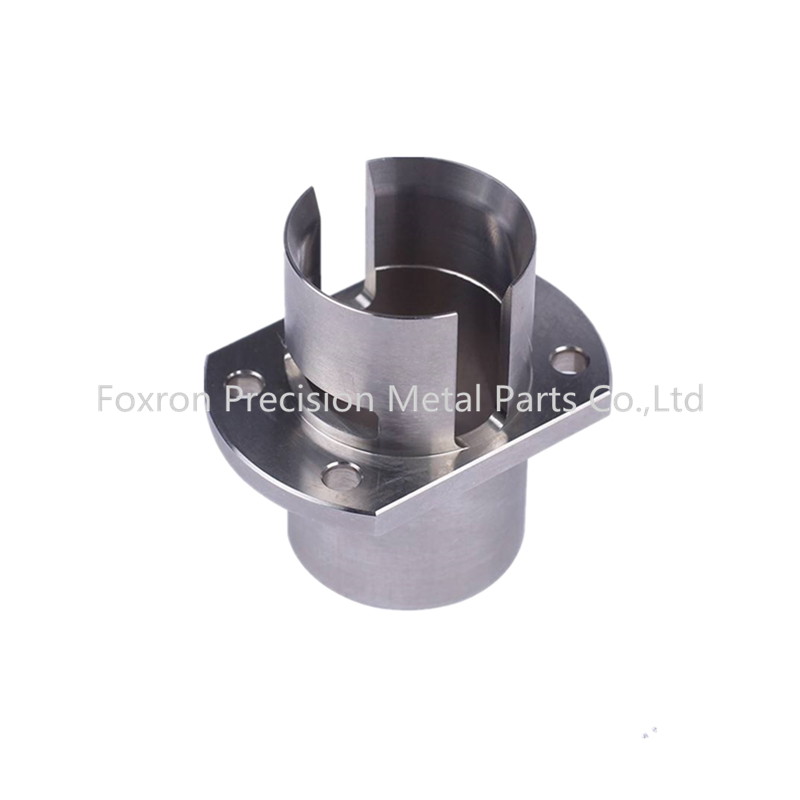

Let's take a look at the physical structure of the aluminum alloy itself. Aluminum alloy has low density, but relatively high strength, which is close to or exceeds that of high-quality steel. It has good plasticity and can be processed into various profiles. It has excellent electrical conductivity, thermal conductivity and corrosion resistance. It is widely used in industry and its usage is second only to steel. . Some aluminum alloys can be heat treated to obtain good mechanical properties, physical properties and corrosion resistance. Hard aluminum alloy belongs to the AI-Cu-Mg series, and generally contains a small amount of Mn, which can be strengthened by heat treatment. It is characterized by high hardness but poor plasticity. Super hard aluminum belongs to the Al-Cu-Mg-Zn series, which can be strengthened by heat treatment. It is the highest strength aluminum alloy at room temperature, but it has poor corrosion resistance and fast softening at high temperature. Wrought aluminum alloy is mainly Al-Zn-Mg-Si series alloy. Although there are many kinds of added elements, but the content is small, it has excellent thermoplasticity and is suitable for forging, so it is also called forged aluminum alloy. The strength of aluminum alloy is also very strong. The tensile strength of pure aluminum is about 80 MN/m2, which is one-fifth of low-carbon steel. But after heat treatment strengthening and alloying strengthening, its strength will increase substantially. For example, the commonly used material of aluminum alloy car body is 6005A-T6, and its minimum tensile strength is 360 MN/m2, which can reach the corresponding strength value of low carbon steel. Aluminum alloy maintains its light weight, but its mechanical properties are significantly improved. The application of aluminum alloy materials has the following three aspects: one is as a force-bearing member; the other is as a door, window, tube, cover, shell and other materials; the third is as a decoration and thermal insulation material. The aluminum alloy can be colored after anodizing to make various decorations. The surface of aluminum alloy plates and profiles can be processed by anti-corrosion, embossing, painting, printing and other secondary processing to make various decorative plates and profiles as decorative materials. The cost is low, and the same parts can be produced in large quantities using a processing technology, which is also one of his characteristics. These characteristics directly determine that it is suitable for more and more fields.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121