What are the advantages of computer gong processing? Why is it said that the quality of castings determines computer gong processing?

by:Foxron

2021-11-15

The processing technology of computer gongs is important. With the development of the current era, the requirements for the quality of the workmanship of the products are getting higher and higher. If the quality is not up to the requirements, they will naturally be eliminated, there will be better manufacturers and better workmanship, so Computer gong processing pays attention to technology, and the quality of workmanship is normal. The development path of computer gong processing is not very simple.

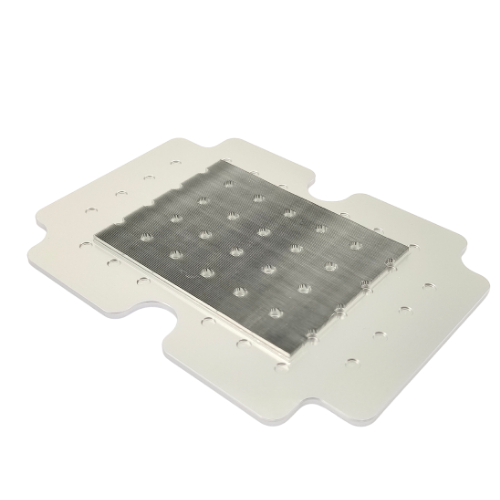

The computer gong is a kind of artificial intelligence, which is controlled by a computer to complete complex processing. The most complicated part of the computer gong lies in the control system. The computer sends various instructions to control the three-axis servo motors of the machine according to the established route to cooperate with each other to process various complex processes, while ensuring high processing accuracy. The most widely used systems in the market are FANUC, Mitsubishi, Siemens, which occupy most of the market share, and there are also systems developed by manufacturers themselves, such as Rhodes, Haas, etc. Is the representative of independent research and development. However, most manufacturers do not have the energy to develop the system, and more are assembled with FANUC and Mitsubishi systems. Domestic system manufacturers include Guangzhou CNC, Huazhong CNC, etc., but they are not mature enough and not stable enough. They are rarely used on computer gongs and are generally used on CNC lathes, CNC milling and other machine tools. The main component of the computer gong fuselage is castings, which are also a major factor affecting the accuracy of computer gongs. It can even be said that the quality of the casting determines the grade of the machine tool and the stability of future use.

1. The number of tooling is greatly reduced, and complex tooling is not required for processing parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification.

2. Further expansion of machine tool compound technology. With the advancement of CNC lathe technology, compound processing technology is becoming more and more mature, including milling-turning compounding, turning-milling compounding, turning-boring-drilling-gear processing compounding, turning-grinding compounding, forming compounding Processing, special composite processing, etc., the precision and efficiency of composite processing are greatly improved.

3. There are new breakthroughs in the intelligent technology of CNC lathes, which are more reflected in the performance of the CNC system. Automatic adjustment of interference and anti-collision function, workpiece automatically exits the safe area after power failure, power-off protection function, machined parts detection and automatic compensation learning function, high-precision machined parts intelligent parameter selection function, automatic elimination of machine vibration during processing, and other functions have come into practical use In the stage of industrialization, intelligence has improved the function and quality of the machine tool.

The computer gong is a kind of artificial intelligence, which is controlled by a computer to complete complex processing. The most complicated part of the computer gong lies in the control system. The computer sends various instructions to control the three-axis servo motors of the machine according to the established route to cooperate with each other to process various complex processes, while ensuring high processing accuracy. The most widely used systems in the market are FANUC, Mitsubishi, Siemens, which occupy most of the market share, and there are also systems developed by manufacturers themselves, such as Rhodes, Haas, etc. Is the representative of independent research and development. However, most manufacturers do not have the energy to develop the system, and more are assembled with FANUC and Mitsubishi systems. Domestic system manufacturers include Guangzhou CNC, Huazhong CNC, etc., but they are not mature enough and not stable enough. They are rarely used on computer gongs and are generally used on CNC lathes, CNC milling and other machine tools. The main component of the computer gong fuselage is castings, which are also a major factor affecting the accuracy of computer gongs. It can even be said that the quality of the casting determines the grade of the machine tool and the stability of future use.

1. The number of tooling is greatly reduced, and complex tooling is not required for processing parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification.

2. Further expansion of machine tool compound technology. With the advancement of CNC lathe technology, compound processing technology is becoming more and more mature, including milling-turning compounding, turning-milling compounding, turning-boring-drilling-gear processing compounding, turning-grinding compounding, forming compounding Processing, special composite processing, etc., the precision and efficiency of composite processing are greatly improved.

3. There are new breakthroughs in the intelligent technology of CNC lathes, which are more reflected in the performance of the CNC system. Automatic adjustment of interference and anti-collision function, workpiece automatically exits the safe area after power failure, power-off protection function, machined parts detection and automatic compensation learning function, high-precision machined parts intelligent parameter selection function, automatic elimination of machine vibration during processing, and other functions have come into practical use In the stage of industrialization, intelligence has improved the function and quality of the machine tool.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121