What are the detailed explanations of industrial aluminum profile processing?

by:Foxron

2021-11-24

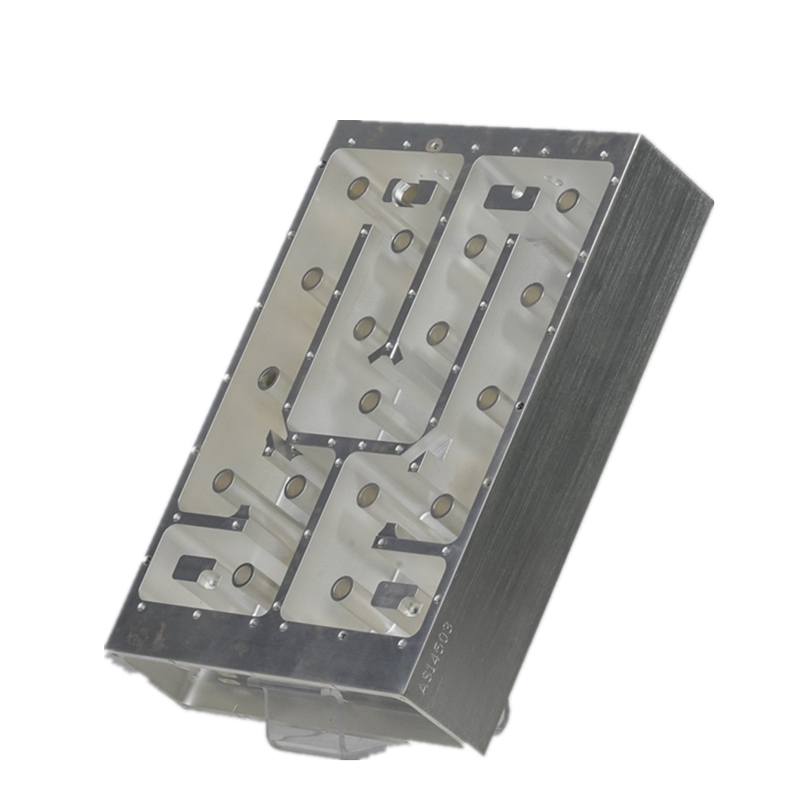

In addition to the special accidents of mold opening and customization, industrial aluminum profiles are also very special after deep processing. There are many aluminum profile factories in China, and most of the aluminum profile specifications are very complete. Series like 20, 30, 40 and even 90, 100, 120 are available from stock all the year round. However, there are only a few manufacturers that can do deep processing, and even fewer can do deep processing to a certain level. Aluminum profile processing includes the processing of aluminum profile itself and the processing of aluminum profile frame products. The processing of aluminum profile itself mainly includes cutting, drilling, tapping, and surface treatment. In addition to these basic processing techniques and methods, the processing of aluminum frame products also requires customized cutting, drilling, tapping and surface treatment according to the designed drawings. For example, the length of the cutting, the position of the hole, the size of the hole, the size of the tap, the surface does not need to be customized, and so on. If you want to make aluminum profile processing to a new level, which is different from other manufacturers in the market and more competitive, what needs to be done? Taking Qiyu Metal as an example, let us understand what to do to make products of new heights. The so-called new height of aluminum profile processing actually means that the processed products are better than others, the processing methods are more efficient than others, and the processing costs are lower than in the market. Cost is something that any entrepreneur has to pay attention to and try to reduce it. With lower processing costs, your product will be less competitive in terms of price in the market. The investment in processing does not seem small, such as more than a dozen production lines, 30+ high-precision imported CNC control centers, multiple double-head CNC precision cutting equipment... These undoubtedly increase the cost. However, because of these advanced and precise equipment, the production and processing costs have been greatly reduced, the time cost has been reduced, and the loss has been reduced. All these add up to reduce the total cost.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121