What are the general forms of CNC lathe processing and production?

by:Foxron

2021-09-26

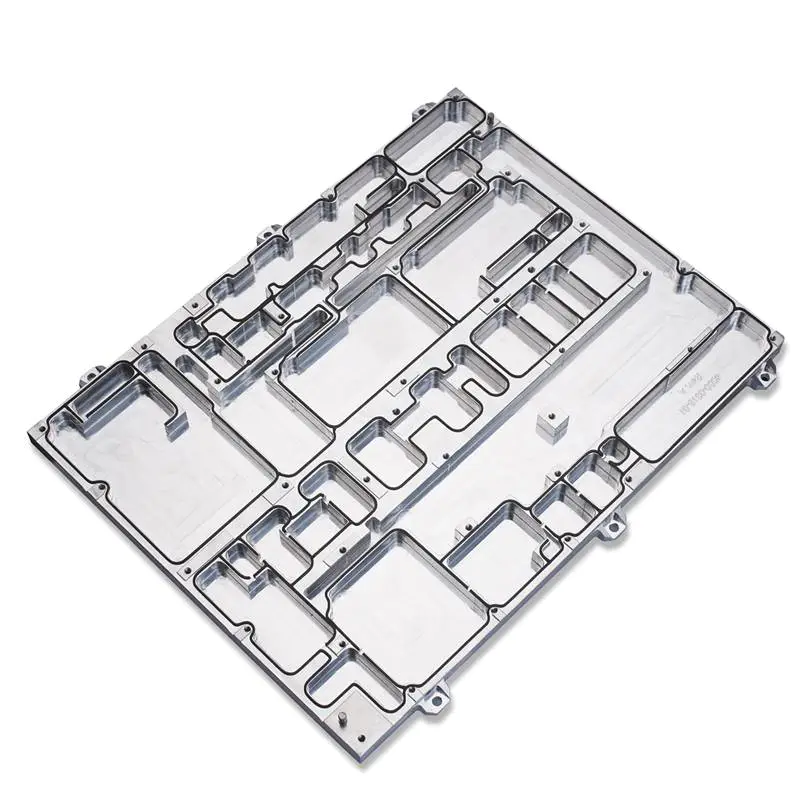

u200b The application of CNC lathe processing equipment is one of the foundations of the competitiveness of the enterprise. The workpiece processing requirements in precision machining generally use the form of CNC lathe processing to perform precision machining of parts.u200b When the mechanical processing plant performs precision machining, it not only meets the customer's workpiece processing technical requirements, but also has the required performance. At the same time, it should pay attention to the improvement of production efficiency and worker efficiency, so that it can bring customers more economical and long-term effective service. First of all, after receiving the customer's drawing processing requirements, before starting the precision machining, it is necessary to select a suitable CNC machine tool and write several sets of economical and profitable processing procedures. Then formulate a suitable machining plan for the CNC machining of precision parts, analyze the drawings of the parts to be processed, perform parts on the parts to be processed, and adopt appropriate processing techniques. In the processing of precision mechanical parts, it is important to write and design the process flow, because the process steps of the part processing, the selection of benchmarks, the selection of processing tools, the selection and installation of fixtures, and the determination of processing strategies and process parameters affect the product Quality. The spindle control of the old CNC machine tools generally adopts DC servo or AC analog servo drive system. According to the needs of use, the original drive device and spindle motor can be used instead of the AC digital servo drive system or the inverter control. The original drive system can also be retained, such as a good AC analog servo drive system; the DC servo drive system can retain a good DC motor and use a new DC servo control device to replace the old drive device.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121