What are the operating steps in the manufacturing process of fixture machinery

by:Foxron

2021-11-25

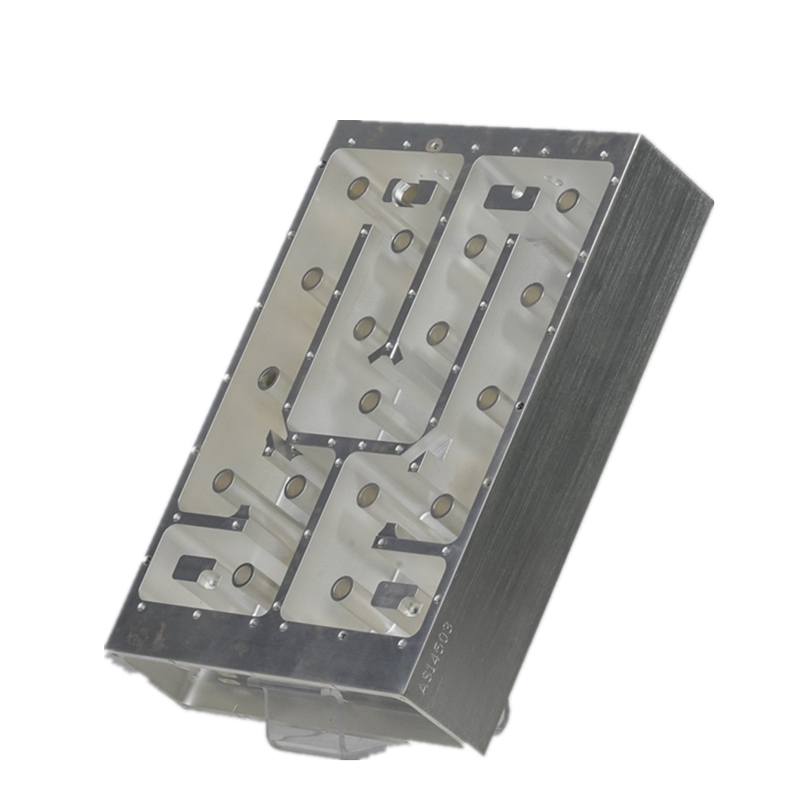

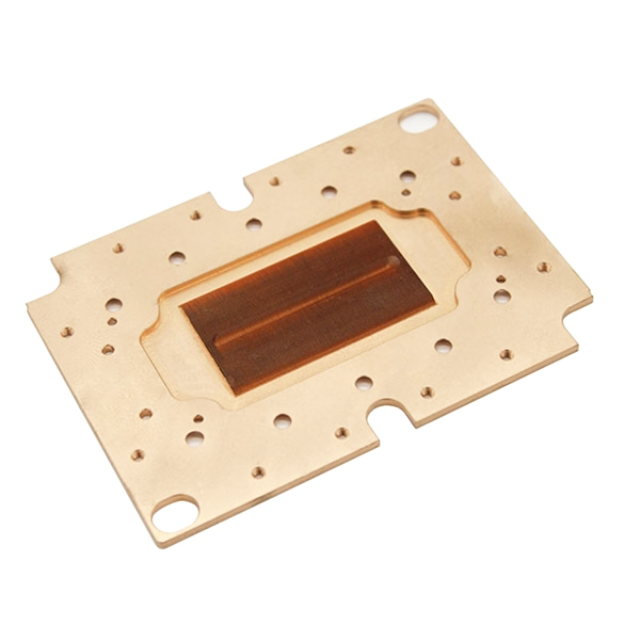

Fixture: A device used to fix the processing object during the mechanical manufacturing process so that it occupies the correct position to accept construction or inspection. (1) Assemble the two sequence 4 engine liner pipes to the sequence 1 support rod according to the 'strut welding assembly' drawing, and place them on the clamp body. The sequence 1 support rod is positioned by the stopper pin and the baffle. The screw clamp clamps the sequence 1 support rod; at the same time, the two pieces of sequence 4 engine liner are positioned by the bolt, and the quick-release screw clamping device clamps them; (2) After spot welding, loosen the quick-release type Screw the clamping device, pull out the pin, remove it for welding; (3) Place the weldment on the clamp body, position the weldment by the stop pin and baffle, and clamp the weldment by the screw clamp; The assembly of the nut M6 and the horn support is placed on the weldment and is positioned by the conical pin on the screw clamping mechanism and the groove on the pressure plate of the screw clamping mechanism and clamped by the screw clamping mechanism; (4) Perform three-sided welding on the assembly of nut M6 and the horn support and the brace, and then loosen all screw clamps. The pressure plate of the screw clamping mechanism of the assembly of the clamping nut M6 and the horn support is bounced by the spring. The positioning cone pin is then separated from the weldment, then the pressing plate is pushed out so that one end is separated from the stud of the screw clamping mechanism, the pressing plate is rotated to the side of the weldment, and then the weldment is taken out.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121