What are the processing technology and surface treatment of precision hardware parts?

by:Foxron

2021-11-13

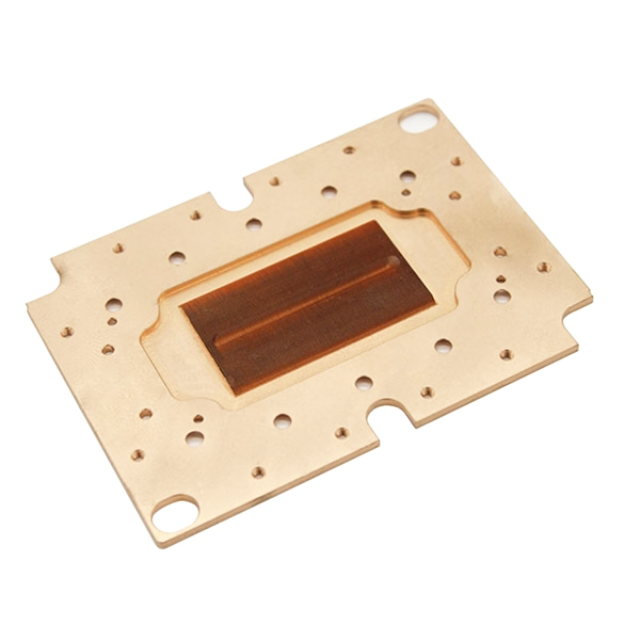

Precision hardware parts not only have a wide range of types and specifications, but also play an irreplaceable role in equipment for various applications. Hardware parts processing is an ideal part that uses raw materials to complete various processing techniques. At present, there are more than ten types of metal products actually operated in the material market, with hundreds of products. For example: stainless steel, copper, aluminum, iron, iron, aluminum alloy and other raw materials are processed on customer drawings or samples through lathes and milling machines. Drilling machines, polishing machines, etc. become various ideal parts. Fu Rui Zhizhi is a machining factory with more than ten years of CNC machining experience. It has a complete set of equipment, CNC turning/milling/grinding/drilling/processing. Partners with parts processing needs are welcome to contact us for quotation. 1. What are the precision hardware parts processing technology? The cost of precision hardware parts is higher than that of plastic parts. Depending on the process used, it can be a little higher or much higher. Here we introduce some common processing techniques of hardware parts. 1. Sheet metal: Sheet metal molds are produced quickly and cheaply, and the delivery time is very short. Sheet metal can be a good alternative to injection-molded plastics for internal structural components because it provides greater flexibility in the early stages of the design process, when the product may still change or the product's prediction is unclear. 2. CNC machining: CNC is a cost-effective solution for machining parts with complex shapes and strict tolerances. CNC precision machining can machine almost any shape, as long as the rotating cutting tool can approach the material. 3. Turning: Turning technology includes cutting, end face, threading, forming, drilling, knurling and boring. For the surface processing of hardware parts, if you want to have a precision bearing surface in a complex machine, turning is usually a good choice. 4. Electric discharge machining: Wire EDM (EDM) is a high-precision technology that can cut almost any conductive material. The thin, charged EDM wire installed between two mechanical rails forms one electrode, and the cut material forms the other electrode. The electrical discharge between the two electrodes (wire and workpiece) generates sparks for cutting the material. Since the live wire never touches the workpiece during EDM processing, this process can be used to manufacture very small and precise parts that require precision and complexity that cannot be achieved by traditional machining. Fu Rui Zhizhi is a CNC precision processing factory with more than ten years of CNC machining experience. It has a complete set of equipment, CNC turning/milling/grinding/drilling/processing. Partners with parts processing needs are welcome to contact us for quotation. Second, the surface treatment of precision hardware parts The surface treatment of hardware parts is another common post-processing technology, and its surface processing subdivisions can be divided into: painting processing, electroplating technology, surface polishing processing and so on. 1. Spray paint processing: At present, most hardware factories use spray paint processing technology when producing large hardware products, and use spray paint to avoid rusting of hardware parts, such as: electrical enclosures, handicrafts, etc. 2. Electroplating technology: Electroplating is a common processing technique in the processing of hardware parts. The surface of the hardware parts is electroplated with modern technology to ensure that the product will not be moldy or embroidered after long-term use. The common electroplating processing of CNC precision machining includes: screws, stamping parts, auto parts, small accessories, etc. 3. Surface polishing process: The surface polishing process is generally used for daily necessities. For example, through the surface burr treatment of hardware products and the processing of spiral bevel gear parts, spiral bevel gears are metal parts made by punching, so the punching corners of spiral bevel gears are very sharp. The sharp corners need to be polished to a smooth surface to avoid damage to the equipment during use. Polishing is to keep the product bright, so the precision metal processing technology we use daily is very extensive, especially for some products that are prone to pilling and burrs. Polishing is an essential step. The article mainly introduces some common hardware parts processing technology. Dongguan Fu Rui Precision Hardware Products Co., Ltd. is equipped with complete precision machining equipment, CNC machine tools, and testing equipment. It has more than ten years of precision machining experience. In the process, we pay attention to the full inspection of product quality and strict control of product quality, which can provide a one-stop service that saves effort and effort. By browsing the article, you can understand that the hardware parts are not only various in types and specifications, but also play an irreplaceable role in various application equipment. Hardware parts processing is an ideal part that uses raw materials to complete various processing techniques.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121