What are the technological processes of CNC lathes?

by:Foxron

2021-11-22

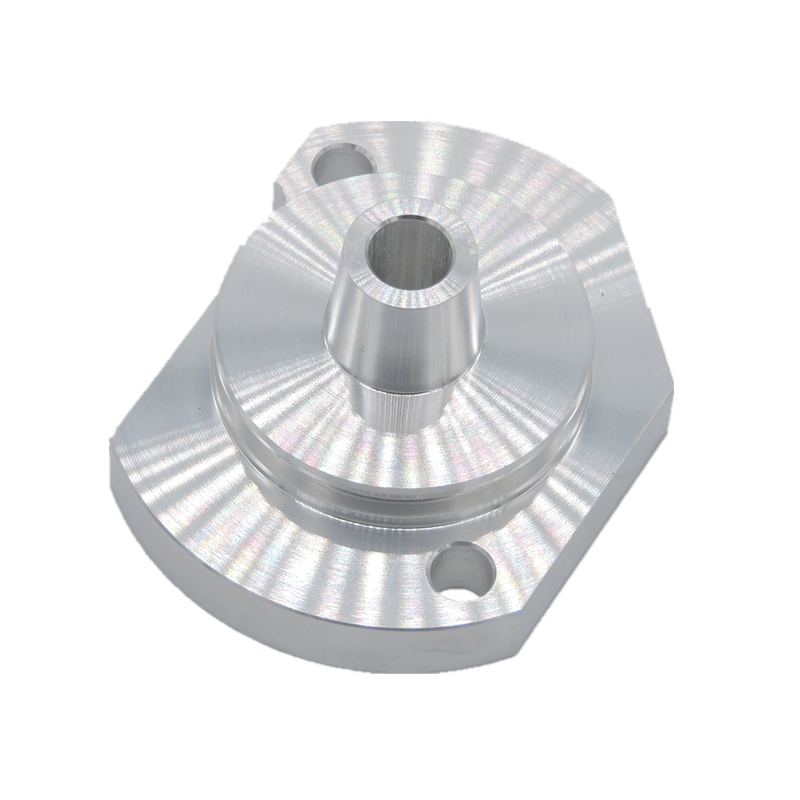

On a lathe, the rotary motion of the workpiece and the linear or curved motion of the tool are used to change the shape and size of the blank and process it to meet the requirements of the drawing. Turning is to use the workpiece to rotate relative to the tool on the lathe to cut the workpiece Machining method. The cutting energy of turning is mainly provided by the workpiece rather than the tool. Turning is the most basic and common cutting method, and it occupies a very important position in production. Turning is suitable for processing revolving surfaces, most of which have revolving surfaces All of the workpieces can be processed by turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads and rotary forming surfaces, etc. The tools used are mainly turning tools. Among all kinds of metal cutting machine tools, lathes are the most widely used The first category, accounting for about 50% of the total number of machine tools. Lathes can not only use turning tools to turn the workpiece, but also use drills, reamers, taps and knurling tools for drilling, reaming, tapping and knurling operations. According to different process characteristics, layout forms and structural characteristics, lathes can be divided into horizontal lathes, floor lathes, vertical lathes, turret lathes, and copying lathes, etc., most of which are horizontal lathes. CNC turning processing is modern A typical representative of manufacturing technology, it has increasingly wide applications in various fields of manufacturing, such as aerospace, automobiles, molds, precision machinery, household appliances and other industries, and has become an indispensable processing method for these industries. For processing on CNC machine tools To produce qualified parts, first need to analyze and determine the process and process parameters of the part according to the accuracy and calculation requirements of the part drawing, and use the specified CNC programming code and format to compile a suitable CNC machining program. The programming must pay attention to the specifics. The numerical control system or machine tool should be programmed in strict accordance with the provisions of the machine tool programming manual. However, from the essence of the content of numerical control processing, the various instructions of each numerical control system are set in accordance with the actual processing requirements.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121