What should be paid attention to when machining CNC precision parts?

by:Foxron

2021-10-02

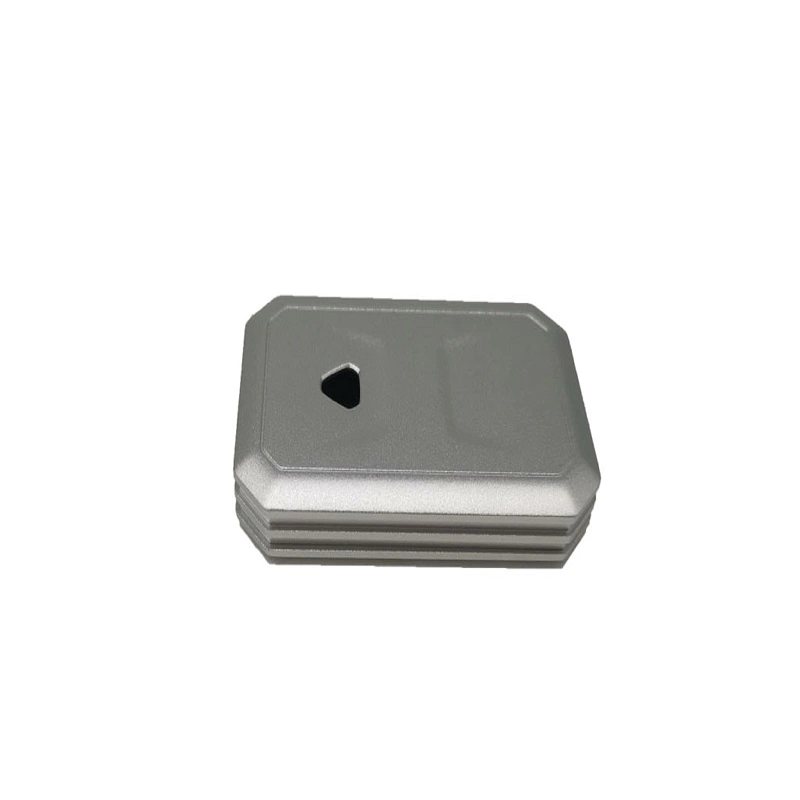

u200bWhen machining CNC precision parts, the materials we generally choose are steel or copper that is relatively easy to cut. The free-cutting steel is generally steel with a relatively high sulfur content or phosphorus content. In the steel, the sulfur and manganese elements are usually manganese sulfide. In the form of, manganese sulfide can make the steel more lubricated and easier to cut to improve its machinability, so what should be paid attention to when machining CNC precision parts? u200b1. When the workpiece is clamped and aligned, only the lowest speed state can be used for alignment, or the chuck can be manually adjusted for alignment. It is absolutely not possible to perform alignment in the high-speed state. 2. If you need to change the rotation direction of the spindle, you must not change the rotation direction suddenly, but stop the spindle first before proceeding. 3. The tool gasket on the machine tool should be flat and straight, and the width should be the same as the width of the bottom surface of the tool, and the tool should not be extended too long during installation. 4. In CNC precision parts processing, if it is necessary to brake the spindle rotation, the reverse method must not be used. In actual applications, precision parts must have higher accuracy and more refined, the more they can reflect the processing level and quality. At the same time, these products are more popular with consumers. Generally speaking, CNC machining has incomparable advantages and characteristics in processing. The quality of its products is usually higher. 1. First of all, the production efficiency of CNC precision parts processing is higher. CNC parts processing can process multiple surfaces at the same time. Compared with ordinary lathe processing, it can save a lot of procedures and save time. The quality of parts is much more stable than that of ordinary lathes. 2. CNC precision parts processing has an irreplaceable role in the development of new products. Generally speaking, parts of different complexity can be processed through programming, while modification and update of the design only need to change the program of the lathe, which can Greatly shorten the product development cycle.u200b

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121