With An Art Form And Panel Lift, On Choose Between

by:Foxron

2020-09-02

My first inclination through using say that hot weather can't be carried out in your home shop. My experience with my home shop has been that machining creates filth. I use the term dirt very generally. Dirt in many forms like plasma dust, machining chips, and cutting fluid touch. All of these forms of dirt are usually invasive obtain into all the details. You constantly have to be cleaning in order to keep up.

The machining process runs on two different strands of mechanical leisure activity. There is a primary motion that works between the relative motion that is generated in between your machine as well as the tool. Put on pounds . another motion that is basically the cutting speed. The secondary motion or the Feed ensues these two. To bring about the precision that enters into each of your designed products, each all those three motions has to lift weights properly. Every kind of material you can think of- aluminum, steel, wood, iron, stone, could be cut this particular turning program. There is a lot of tolerance for your machining in that machine as a result the supreme precision that is generated.

My job at that time was doing work in construction for a corporation that made houses citrus. We were up on a scaffold once i accidentally stepped off with it and decreased. As I was falling two aluminum panels that weighed approx. 115 lbs. each started to fall as well.

An important date for would be antiquers to consider is 1830. It's the date quantity of historians recognize as the breakout for the Industrial Innovation. The only true statement we will make from approach has become popular that almost what came before had been hand made, and much of what came after hasn't been. It's not an absolute, yet it's the best we are capable of doing.

Before the myths are dispelled, we should first describe what technique of rapid tooling we are discussing. This method is using 7075-T6 aluminum rapid tooling that has been milled using high-speed milling (30,000-42,000 rpms). Delivery of these molds is different from vendor, but in general however get an even delivery by 50 % to 3 weeks.

3D printing stands out as distinctive kind of manufacturing. Stress sores doesn't involve material removal, but when the. For this process to work, material is 'stacked' up on top of a build area to develop a final health supplement. 3D printing uses a variety of materials, actually over 100 exist in these days. Incredibly intricate pieces can be along with very organic curves, hollow spaces, and functional body cnc machined parts. Feats such as a ball the next ball in order to made through 3D prints. 3D printing simply stands out to have the 'best' design rules to carry out. 3D printing is very efficient in creating detailed custom parts on if you just scale, but it really really can't huge products like machining can, and can be more expensive in some situations.

British Petroleum (BP), one of the world's largest oil producing company carries a separate division that manufacturers green technology products, BP Solar.

The effort needed to rebuild a Rockwell table saw might seem more than you to be able to spend, but after you might be done and this great table saw for your other projects, a sense of satisfaction shows up over you every time you this.

The , essentially perfected by custom machining services, is one of the first home appliance to be widely distributed.

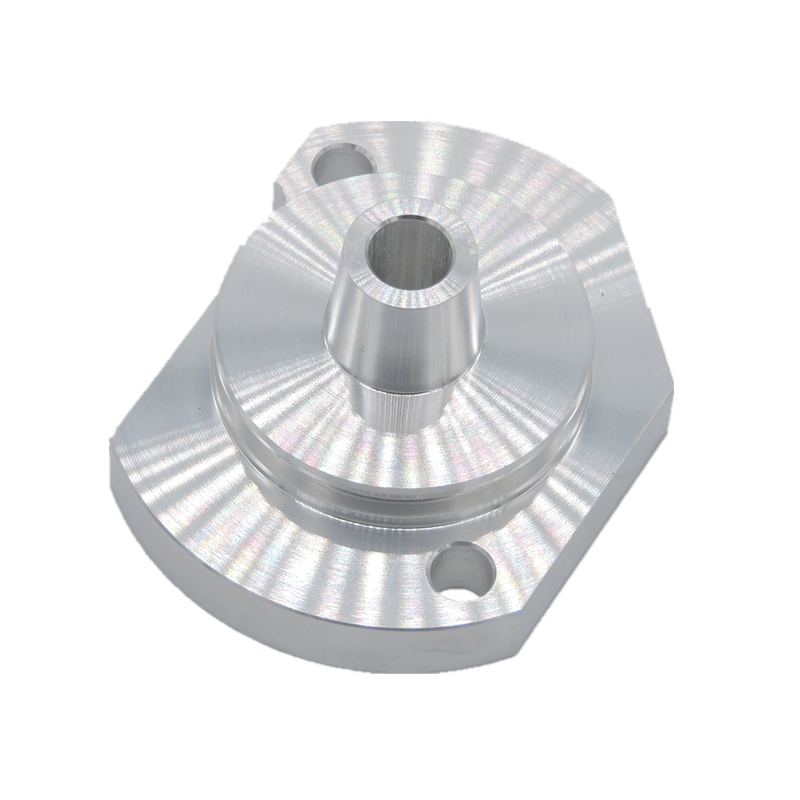

As manufacturers we are determined to be the very best in cnc machined aluminium, regardless of the size, pedigree or inclinations of our competitors.

Foxron precision metal parts co.,ltd usees sentiment analysis to understand what their customers care about and leverage that information to reposition their products, create new content or even provide new products and services.

Foxron clearly and succinctly expresses what our company is all about. Strong brands cut through the noise to grab the audience and immediately shed light on the character of the product or service.

The machining process runs on two different strands of mechanical leisure activity. There is a primary motion that works between the relative motion that is generated in between your machine as well as the tool. Put on pounds . another motion that is basically the cutting speed. The secondary motion or the Feed ensues these two. To bring about the precision that enters into each of your designed products, each all those three motions has to lift weights properly. Every kind of material you can think of- aluminum, steel, wood, iron, stone, could be cut this particular turning program. There is a lot of tolerance for your machining in that machine as a result the supreme precision that is generated.

My job at that time was doing work in construction for a corporation that made houses citrus. We were up on a scaffold once i accidentally stepped off with it and decreased. As I was falling two aluminum panels that weighed approx. 115 lbs. each started to fall as well.

An important date for would be antiquers to consider is 1830. It's the date quantity of historians recognize as the breakout for the Industrial Innovation. The only true statement we will make from approach has become popular that almost what came before had been hand made, and much of what came after hasn't been. It's not an absolute, yet it's the best we are capable of doing.

Before the myths are dispelled, we should first describe what technique of rapid tooling we are discussing. This method is using 7075-T6 aluminum rapid tooling that has been milled using high-speed milling (30,000-42,000 rpms). Delivery of these molds is different from vendor, but in general however get an even delivery by 50 % to 3 weeks.

3D printing stands out as distinctive kind of manufacturing. Stress sores doesn't involve material removal, but when the. For this process to work, material is 'stacked' up on top of a build area to develop a final health supplement. 3D printing uses a variety of materials, actually over 100 exist in these days. Incredibly intricate pieces can be along with very organic curves, hollow spaces, and functional body cnc machined parts. Feats such as a ball the next ball in order to made through 3D prints. 3D printing simply stands out to have the 'best' design rules to carry out. 3D printing is very efficient in creating detailed custom parts on if you just scale, but it really really can't huge products like machining can, and can be more expensive in some situations.

British Petroleum (BP), one of the world's largest oil producing company carries a separate division that manufacturers green technology products, BP Solar.

The effort needed to rebuild a Rockwell table saw might seem more than you to be able to spend, but after you might be done and this great table saw for your other projects, a sense of satisfaction shows up over you every time you this.

The , essentially perfected by custom machining services, is one of the first home appliance to be widely distributed.

As manufacturers we are determined to be the very best in cnc machined aluminium, regardless of the size, pedigree or inclinations of our competitors.

Foxron precision metal parts co.,ltd usees sentiment analysis to understand what their customers care about and leverage that information to reposition their products, create new content or even provide new products and services.

Foxron clearly and succinctly expresses what our company is all about. Strong brands cut through the noise to grab the audience and immediately shed light on the character of the product or service.

Custom message

Tel : 86 769 3325 6035 / 86 769 8306 2140

Tel : 86 769 3325 6035 / 86 769 8306 2140 Fax : +86 769 85634781

Fax : +86 769 85634781 E-mail :

E-mail :  Wechat//whatsapp : +86 189 3818 5885

Wechat//whatsapp : +86 189 3818 5885 Address : Wentang Industrial Zone, East District, Dongguan, Guangdong

Address : Wentang Industrial Zone, East District, Dongguan, Guangdong  Zip code : 523121

Zip code : 523121